VIBRATIONS & PIEZO TECHNOLOGY

OUR TECHNOLOGICAL FOCUS

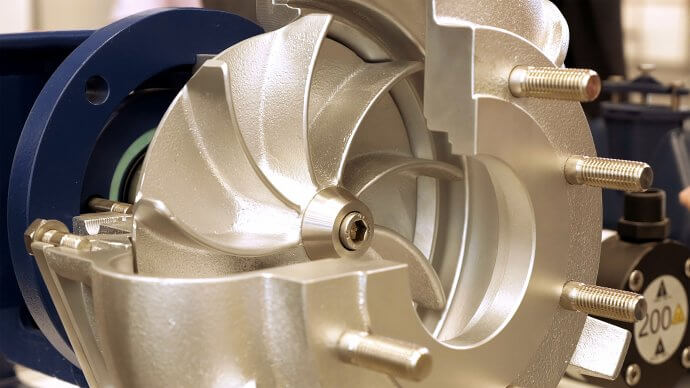

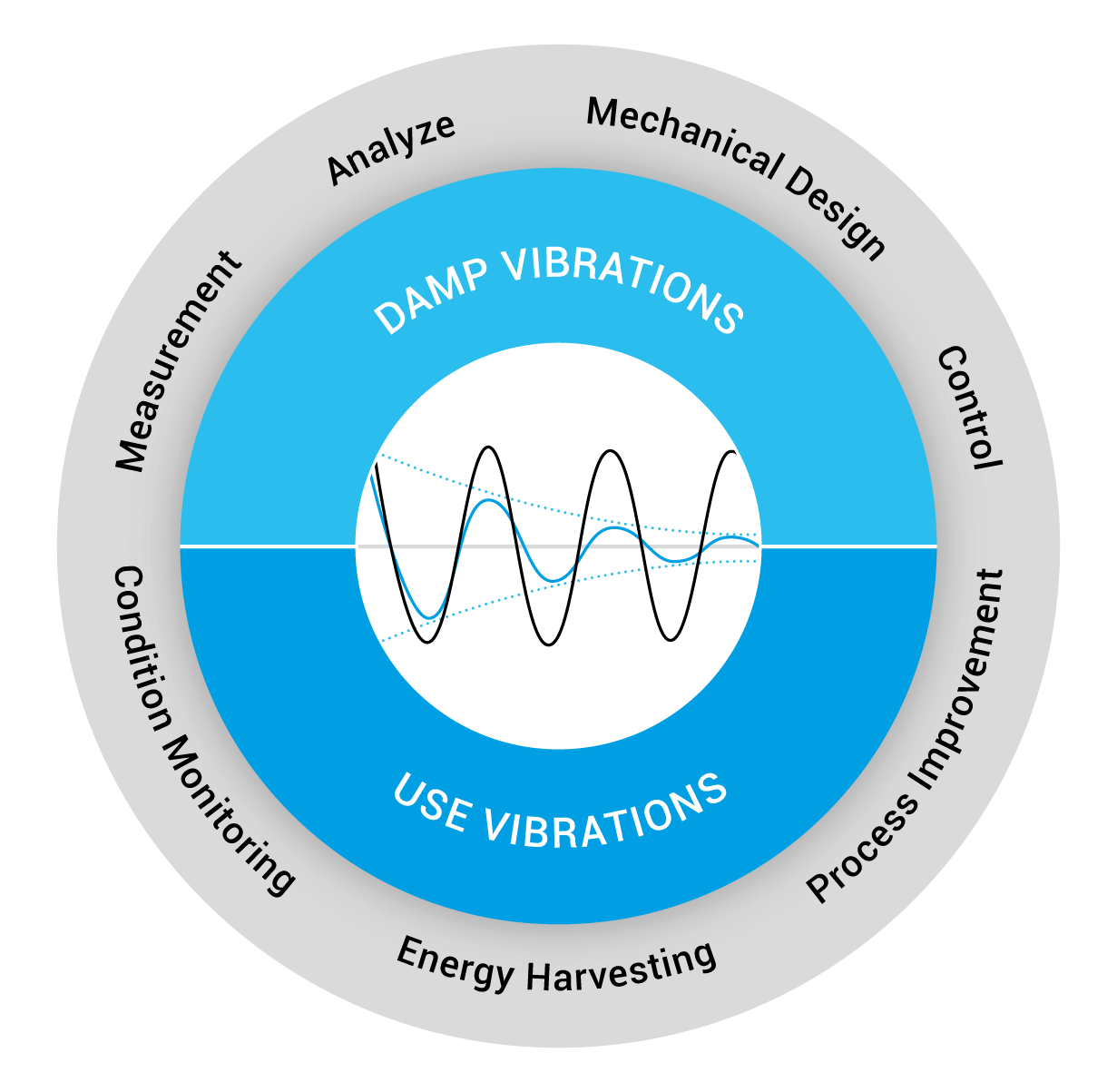

Shorter cycle times and lightweight construction also in classical plant and machine construction often lead to an increase of unexpected mechanical vibrations. Depending on the application, these vibrations can lead to quality problems, noise or even safety-relevant vibrations of machines or buildings. In many cases, however, mechanical vibrations are generated on purpose or are serve as source of energy to supply sensors.

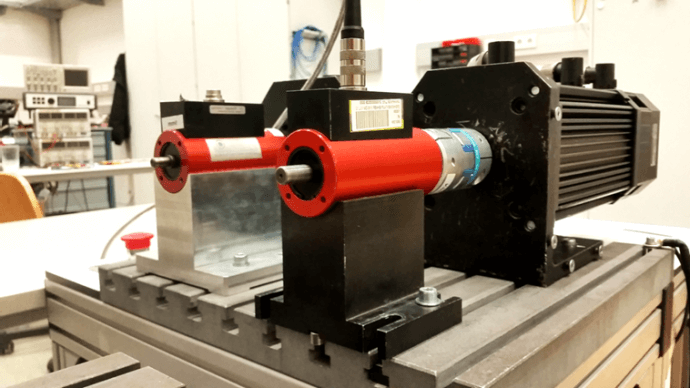

MEASUREMENTS

Mechanical and acoustic measurements on machines or components are carried out for analyses, verifications or parameter determination either directly on site at the customer or at LCM.

VIBRATION TECHNOLOGY

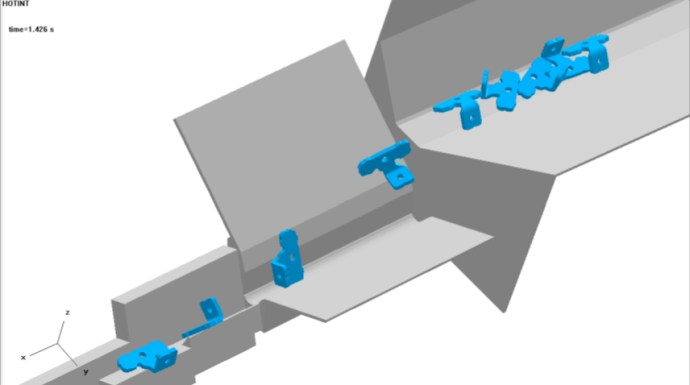

Vibrations and noise can be measured and analyzed at existing plants in order to take countermeasures. However, it is better to design the vibration behaviour supported by simulations during the development phase.

VIBRATION DAMPING

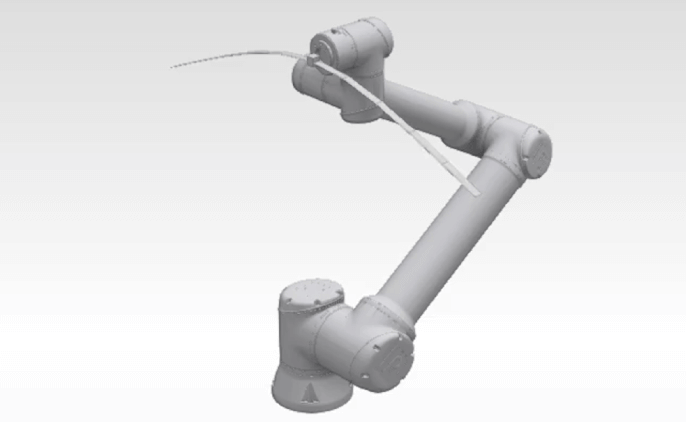

Multiple methods exist to reduce vibrations efficiently. Passive methods rely on a change of the mechanical structure without the need of any additional actuators or sensors. Active concepts either use actuators to generate (counter-) forces or realize a more sufficient motion profile with appropriate control concepts.

ACTUATORS & ENERGY HARVESTING

In order to generate mechanical vibrations or to use them as energy sources, suitable actuators and electronics are required. Different physical concepts are used depending on amplitude and frequency range.

PIEZO TECHNOLOGY

Piezoelectric components can be used as sensors for vibrations, for energy harvesting or as compact actuators in a wide frequency range.

An optimal design of the overall system (mechanics + electronics) offers great advantages here.

OUR SERVICE OFFER

Knowledge transfer

We offer you a wide range of possibilities to build up your competencies, to advise you on the best solution strategy or to give you an overview of the current state of the art – from presentations or webinars to training courses and workshops, flexible and individually plannable.

Development

We develop for you from the first idea to the finished prototype. Especially in case of resource bottlenecks in your own development team or if technological knowledge is necessary that is not available in the company, we offer you to carry out the complete R&D project from the idea to the prototype.

Co-Development

We do R&D together with your development department. As input for new solution strategies, in case of personnel bottlenecks or if competence building in your own development team is required, we offer you the opportunity to carry out subtasks or work packages together with us

Optimization

We will find an optimal solution for you to improve existing machines and systems, as well as the optimal design for new applications. Our offer includes the optimal design of new components for vibration damping, energy harvesting or piezoelectric systems as well as the analysis and reduction of unwanted vibrations.

Measurement service

From the creation of the measurement plan and the preparation of the measurement, to the execution of the measurement directly at your site or at our laboratory, to the evaluation and analysis. We work in such a way that the data relevant to you are measured and analysed quickly but carefully and as far as possible without impairing the operation.

APPLICATIONS & BRANCH OF INDUSTRY

ADDITIONAL INFORMATION: LINKS & DOWNLOADS

- MEASUREMENT BASED (VIBRATION-) ANALYSIS

- ACTIVE AND PASSIVE VIBRATION DAMPING

- HAPTIC FEEDBACK

- PIEZOELECTRIC VIBRATORY CONVEYOR

- ACTIVE VIBRATION DAMPERS

- CONTROL OF FLEXIBLE STRUCTURES

- BROADBAND VIBRATION COMPENSATION OF PLATE WITH PIEZOELECTRIC ACTUATORS/SENSORS

- VAMOS – VIBRATION ANALYSIS AND MONITORING SYSTEMS

- BONEBRIDGE – HEARING IMPLANTS

In coopeartion with our partner, the Institute for Technical Mechanics of Johannes Kepler University Linz, we can use the following devices:

- Sensors for mechanical properties

- position (inductive, laser)

- acceleration

- velocity (1D vibrometer, 2D scanning vibrometer)

- force and torque

- Accoustic measurement

- STSF 18-ch microphone array

- 36-ch Wheel Array

- sound intensity probe

- 1/2-inch Free-Field Microphone

- Excitation of vibrations

- shaker and impulse hammers

- Data logging and evaluation

- Pulse, measurement amplifiers, filter systems

REFERENCE & REPORTS

Efficient Digital-Hydraulic Control System by LCM

This video demonstrates a highly efficient digital-hydraulic control system called HPC (hydraulic pulse controller) for mobile and industrial applications such as pumps or presses. The hydraulic pulse controller is capable of carrying out short micro dosing resulting...

Leading Indian manufacturer of drive systems for electrically powered vehicles visits LCM

Electromobility is also advancing massively in Asia. Significant growth is expected, especially in the motorcycle segment. The use of optimized drive systems is essential in order to actually achieve the desired goals such as high range, small installation space, low...

Benchmarking Workshop on (active) vibration damping

Benchmarking workshops (also called mechathons when held in the area of mechatronics) can be used to benchmark existing technologies and bring together experts of the same field in order to encourage knowledge transfer and future cooperation. Within the frameworks of...