Measurement Engineering

Based on our numerous R&D projects for technology leaders, we have an excellent measurement infrastructure. Our experienced staff will advise you in advance on the measurement design in order to prevent unnecessary or incorrect measurements, to capture and process data efficiently, and enable validation in the context of modeling and simulation. Thus, nothing stands in the way of a successful project execution through fast, cost-effective and correct measurements.

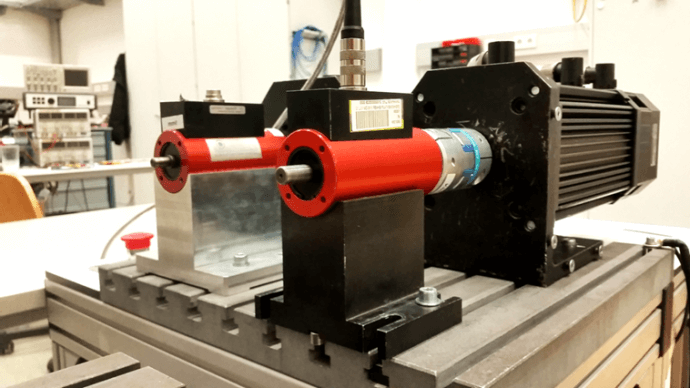

Integrated drives

Measurement of electrical and hydraulic actuators (rotating and linear)

- Efficiency

- Maps

- Losses

- Temperatures

- Vibrations and sound

Vibration measurement on components or machines for analysis, parameterization, verification

- Time signals

- Transfer functions

- Modal analysis

- Operational analysis

- Diagnosis using a waterfall diagram

Measurements on our test benches under laboratory conditions as well as measurements at your location

- System diagnostics

- System monitoring

- System analysis

- Measurement data-based models

- Measurement of large objects and spaces for 3D visualizations

Special Solutions

Measurement tasks which cannot be solved with standard measuring instruments

- Creation of measurement concept

- Selection and procurement of sensor elements

- Manufacturing of electrical supply and interfaces

- Measurement, evaluation and interpretation

- Supervised long-term data acquisition

OUR MEASUREMENT OFFERS

Drive engineering

Requirements

- Pump measurement

- Cylinder measurement

- Valve measurement

- Magnetic measurement

- Efficiency, leakages, friction, wear, characteristic diagrams

Solution:

- Hydraulic motors, pumps, cylinders

- Hydraulic supply up to 2 x 50kW, 200 L / min, 300 bar

- Torque / speed / force measurement

- Pressure / volume flow measurement (50mL / min to 600L / min)

- Gearboxes, flanges, clamping fields

- Magnet development

Electric actuators

Requirements

- Power range from a few watts to 54kW

- Determination of efficiency

- Map measurement

- Measurement of liquid-cooled actuators / drives

- Vibration measurement

- Sound measurements

Solution

- 3 flexible engine test stands

- Yokogawa WT1800 power meter

- Various force and pressure sensors

- Sound and vibration measurement systems

- Thermal camera

Energy Harvesting

Requirements

- Determination of power supply reliability of IoT sensors and devices using energy harvesting

- Long-term characterization of energy harvesting devices (e.g. solar cells)

- Automated measurements at certain applications on site

Solution

- Portable and wireless characterization device

- Installation on site and startup of the measurement hardware

- Direct measurement at the respective application

- Evaluation of the measurement data and development of the power supply concept

Onsite Measurement

Requirements

- Diagnosis and troubleshooting at the customer’s location

- Analysis of the feasibility with sensor data recording

- Little or no interruptions in productive systems

Solution

- Portable industrial control for measurements

- Flexibly expandable

- Automatic measurements and evaluations

- Evaluation and presentation directly at the customer’s location

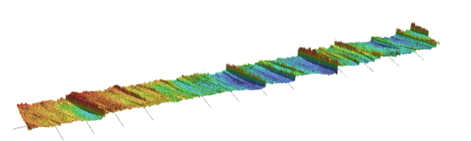

Vibration Measurement

Requirements

- Quantification of undesired noise development in electrical or mechanical (industrial) systems

- Locating the sound sources in operation

- Operational noise measurements

- Acoustical comparison of identical systems

- Validation of finite element simulations

- Quality assurance by comparing identical systems

- Waveform analysis (modal analysis, order analysis)

Solution

- Sound source location

- Sound pressure measurement

- Sound power calculation

- Noise mapping

- Beamforming

- Stimulation by means of an impact hammer and shaker

- Graphic evaluation of the deflection shapes and frequencies

- Comparison of simulation and measurement

Validation

Requirements

- Tuning/calibration of simulation models based on measurements

- Identification of undetermined/unknown parameters and system properties

- Validation of (simulation) models with measurements and tests

- Indirect model-based determination of quantities that are not directly accessible

by measurements - Evaluation of the quality of simulation results (accuracy/error estimates,

uncertainties/tolerances)

Solution

- Multi-objective optimization for model calibration and parameter identification

- User-defined interfaces, data export and evaluation for different simulation

environments - Post-processing methods for the analysis and alignment of simulation results and measurement data

- Individual and standardized test setups or measurement/identification methods

depending on the application - Parameter studies and sensitivity analyses for the assessment of influencing

factors, parameter dependencies and error propagation - Design of Experiment (DoE) techniques for both experiments/measurements as

well as simulation studies, especially for large parameter spacesSound pressure measurement

Thermal measurements

Requirements

- Detect surface temperature, contact-free on dynamic parts e.g. rotating parts

- Locating heat sources in operation

- Comparison of components, circuit boards

- Validation of calculations and simulations

Solution

Room measurements

Requirements

- 3D measurement of large objects, rooms

- Control of dimensions and positions

- Basis for simulation of 3D boundary conditions

Solution

Component measurement

Requirements

- Verification of the roughness of surfaces

- Inspection of geometric tolerances

- Quantification of wear3D measurement of large objects, rooms

Solution

Measurement Equipment

Our measurement tools enable us to measure all kinds of mechanical, electrical, acoustic, hydraulic, thermal and magnetic requirements.

Mechanical

- Position (induktiv, laser)

- Acceleration

- Speed(1D vibrometer, 2D scanning vibrometer)

- Power and moment

- Shaker, impulse hammer, piezoelektric actuators

Acoustic

- STSF 18-ch microphone array

- 36-ch wheel array

- Sound intensity probe

- 1/2-inch free-field microphone

- Seven Bel – Sound Scanner P132

Electrical

- 3 flexible engine test benches 0-54kW / 0-290Nm

- Powermeter WT1800 by Yokogawa with 6 modules

- High quality digital oscilloskope

- Network and spectrum analyzers

Hydraulic

- Pressure / volume flow sensors (up to 10000bar, 600L / min)

- Torque / power measurement

- Distance / acceleration sensors

Thermal

- Thermal camera (Flir SC620)

- Climatic cabinet

- Coolant conditioning: Wittmann Tempro basic C 140

Magnetic

- Magnetizing device

- Gaussmeter

Wireless

- Battery-powered measurement devices

- Energyharvesting (photovoltaic or mechanical)

- Data logger with radio trigger for distributed sensors

- Mobile measuring case with industrial controller

- Bluetooth throughput measurement

Geometric

- 3D laser scanner for entire rooms

- 2D laser scanners

- Stereo cameras, RGBD cameras

- Profilometer (white light)

Vibrations

- Measurements

- Vibration technology

- Vibration damping

- Actuators & Energy Harvesting

- Piezo technology