Robotics

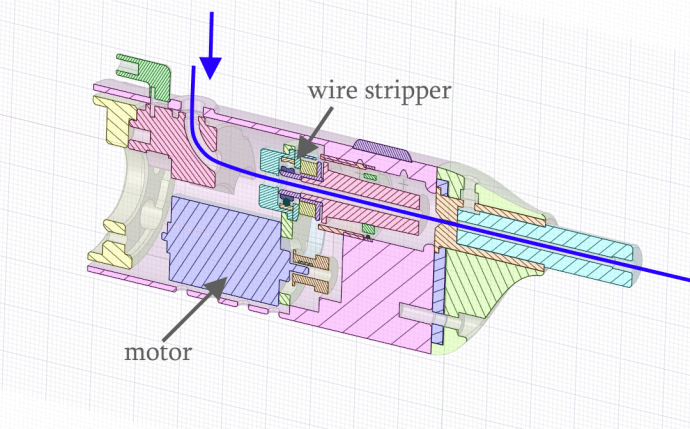

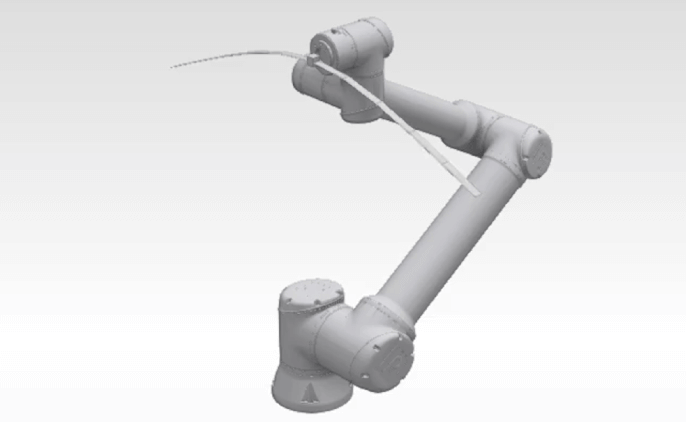

LCM develops solutions with you even outside the usual paths. We analyze your process and demonstrate possible implementation variants with our equipment. We also develop and manufacture suitable tools (end-of-arm tools) for your robot.

Arrange your personal consultation appointment now!

Our Services

Design

We automate your process with ingenuity, design, simulation and cross-industry experience.

Testing

We test the design and process with automated simulations and virtual commissioning.

Operation

Convince yourself by a functional sample/prototype for first tests in our laboratory or directly at your site.

![]()

Funding

We estimate the return on investment (ROI) with you and find a suitable funding for your project.

Reference projects

For each of the above services we present here a reference project. See also the collection of projects projects at the bottom of the page.

DESIGN – Autonomous waste management

In cooperation with the company Brantner, LCM is working on an autonomous robot system with which full waste containers can be replaced by empty ones as needed.

Within our K2 center “Symbiotic Mechatronics” we support this project in many ways. We advise on hardware selection, implement the waste garbage container handling (concept development, development of grippers and holding devices, prototyping, testing) and create a concept for the overall process of the mission “waste container exchange”.

We integrate the robot control into the AGV control and support the chassis realization (implementation opening and closing of the chassis for robots (construction mechanics, actuator selection), design: University of Art Linz). Furthermore, we implement the data connections (level sensors, trackers, etc.) and the monitoring of the development platform.

Using our virtual commissioning tool (Industrial Physics), we simulated the process during container changeover to check accessibility and collision-free operation.

TESTING – Charging device

In a project with the company Ebner Industrieofenbau, the newly developed fully automated charging system of the top-hat furnace HICONSABER was virtually put into operation by LCM.

HThe iPhysics software from Machineering was used for this purpose. By coupling with common CAD tools, iPhysics takes over the plant geometry at the push of a button. Adjustments can be taken over without additional effort by redrawing.

The HICONSABER furnace system is now running to the customer’s complete satisfaction. With the digital twin of the plant created, adaptations and extensions both in the design and in the software can now be checked quickly and without risk in subsequent projects and plant operators can be trained.

OPERATION – Thread recutting

In this feasibility study with Wacker Neuson, the question was whether it would be possible to implement the “thread recutting” process, which had previously been carried out manually with a cordless screwdriver, in an automated and robust manner using a robot.

We realized a functional sample in our laboratory with the currently used (and only slightly adapted) tools and were able to demonstrate the basic feasibility quickly and cost-effectively.

For this purpose, different threads were recut in a range from M8 to M24, which were contaminated by the painting process and corrosion.

The cordless screwdriver was controlled directly via the robot’s control system, in which force and torque measurement are also available.

Funding

Especially for SMEs which are not yet using robotics in production, the (mostly still unknown) costs are often difficult to estimate. In addition to the costs for the feasibility study itself, the effort required for the introduction of robotics is particularly relevant. How long it will take for the robot to pay for itself is determined, for example, with a return on investment (RoI) calculation.

For SMEs, there are numerous (national and regional) funding opportunities for these analyses and modernization processes. LCM is happy to advise here together with the funding agencies. LCM is also continuously involved in various (national or European) funded projects. Here, too, there are always opportunities for Austrian companies to receive attractive funding.

In the context of the DIH² project, for example, LCM was able to successfully support 2 consortia (RoWa Automation with Huber Kunststofftechnik and TCM Systems with RoRa Aviation) in receiving €248,000 each in EU funding.