ELECTRICAL DRIVES

Our technological focus

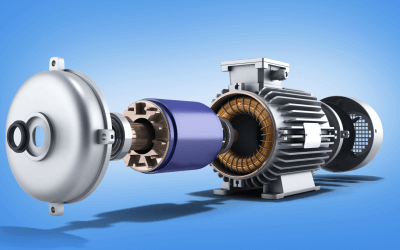

The Linz Center of Mechatronics relies on solutions from a single source for the development of electric drives. All relevant competencies such as simulation, optimization, electronics and prototyping interlock to implement the drive for their application – efficient, robust and cost-effective.

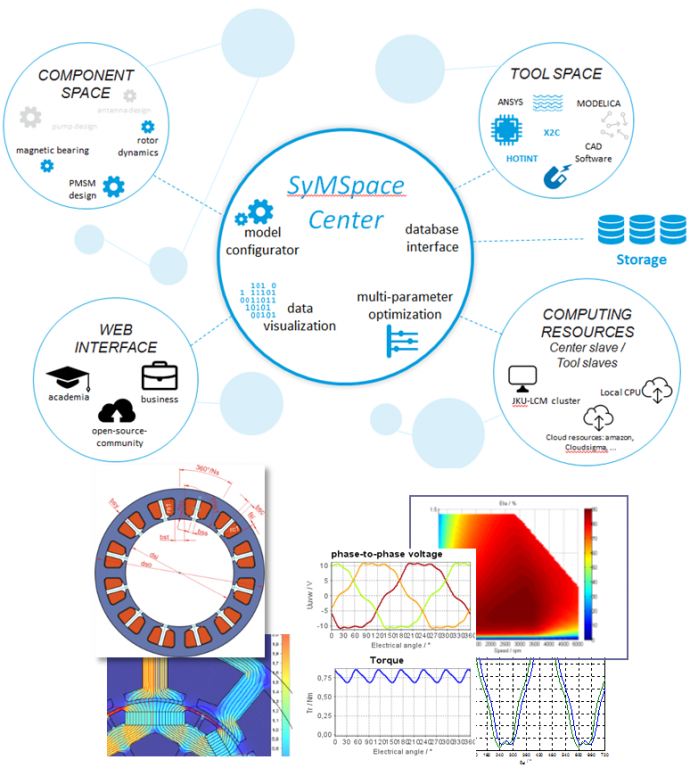

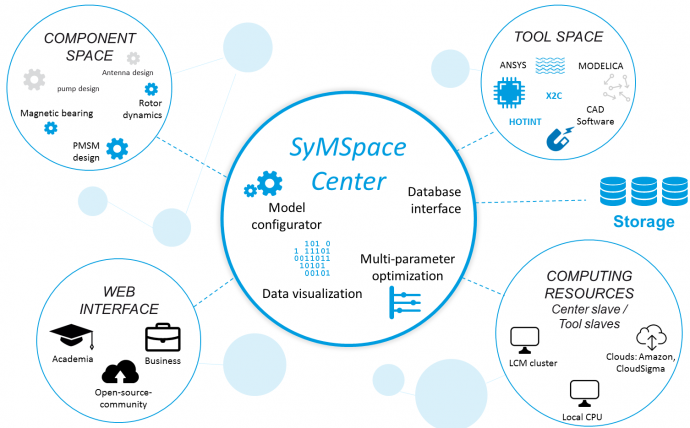

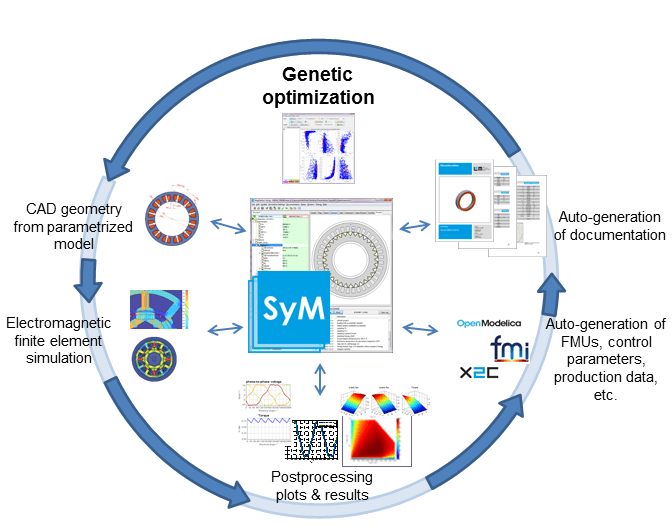

MOTORDESIGN

The design of electrical machines requires complex simulations and optimizations. The overall system (electromagnetics, rotor dynamics, thermal conditions, etc.) counts as much as the details (magnetic losses, torque ripple, current harmonics, etc.). With the SyMSpace MotorBox, LCM also offers a comprehensive software tool on a pay-per-use basis.

POWER ELECTRONICS

Optimized power electronics for optimized drives allows highest efficiency, power density and robustness. With different designs, communication interfaces, safety mechanisms, switching topologies and voltage levels.

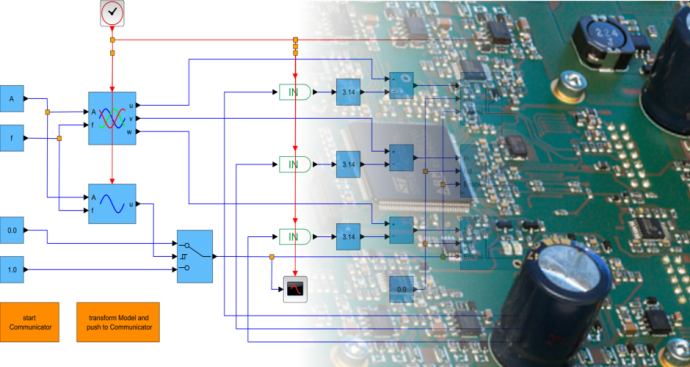

CONTROL OF ELECTRICAL MACHINES

Only the control of the electric machine exploits all potentials. From simple speed controllers to optimized current curves or to sensorless control. With X2C, LCM has developed high-performance software that offers graphic controller programming, online parameter tuning and signal visualization.

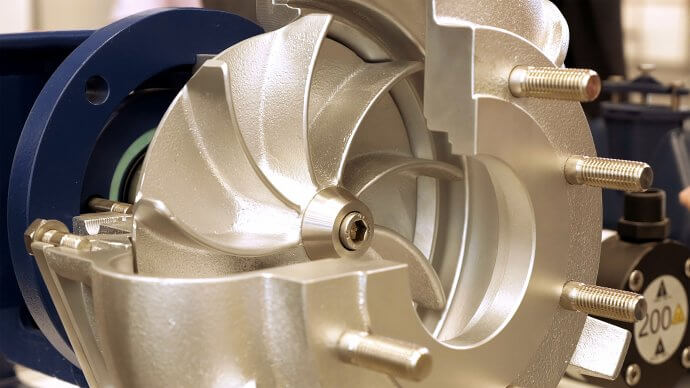

MAGNETIC BEARINGS

Magnetic bearings provide oil-free, abrasion-free operation for maximum lifetime and highest speeds. In addition, rotor and stator can be hermetically separated – without seals, for special requirements regarding aggressive media, high purity, etc.

OUR SERVICE OFFER

ENGINEERING SERVICES

We support you wherever you want.

From concept development to redesign of existing systems to the design of individual components or entire drive systems with support for series implementation or certification – we support you in this. Especially with special requirements regarding power density, efficiency, costs, operating conditions or service life, we bring along our simulation and optimization know-how.

PROTOTYPE CONSTRUCTION AND MEASUREMENT SERVICE

Construction and commissioning of prototypes, measurement at the engine test bench.

Thanks to our in-house production, we are able to quickly and flexibly set up prototypes for electric drives and commission them with existing or newly developed control systems. Surveying on the test bench provides certainty and pushes the systems to their limits – both as part of development projects and as a measurement service.

KNOWLEDGE TRANSFER

If anyone knows, nobody knows.

LCM does not work as a black box but lets customers look into every corner of the development. This enables knowledge building and safeguards technological progress. Upon request, LCM also offers training and seminars on selected topics in drive technology.

LINKS & DOWNLOADS

News & Events

Machine models for the simulation of fault events and shutdown processes

The goal of the recently launched EU project R-PODID (Budget € 23.7 Mio., 33 partners) is to develop an automated, cloud-less, short-term fault prediction for electric drives, power modules and power devices that can be integrated into power converters. As a project...

LCM wins EARTO AWARD 2023

LCM has won the EARTO AWARD 2023 in the category "Impact Delivered" for the development work on the Voith eVSP . We congratulate Hubert Mitterhofer and the Motor Technology Team around Ralf Kobler! Hubert Mitterhofer and his team received the coveted award in the...

On the Benefits of Electric Drives: LCM at the EMC/JKU Congress “CLIMATE / MOBILITY / ENERGY

Our expert for electric drives Hubert Mitterhofer gave a lecture on alternative drives in mobility at the very well attended congress of the electromobility club EMC and the JKU "CLIMATE / MOBILITY / ENERGY". The experience gained from two decades of engine design and...