Your DEVELOPMENT PARTNER

FROM IDEA TO PRODUCT

We develop individual mechatronic solutions for our customers based on economical criteria using advanced knowledge from our in-house research. Depending on the needs of our customers, we carry out the overall development, partake in a development project, or provide individual services.

Our Projects are as diverse as our customers

Our customers range from small and medium-sized enterprises to international automotive groups. Our main customers from the automotive, mechanical engineering, electrical, agricultural machinery, medical technology, construction machinery, and automation sectors validate our development and innovation expertise.

SELECTED REFERENCES

ELECTRICAL DRIVES

SMALL HYDRO GENERATOR PROJECT

The revitalization of small river power plants for the generation of electricity is pivotal to sustainability. The cost-benefit ratio of small power plants can be challenging.

LCM SOLUTION

- Design and construction of a small hydropower generator (900 kW) with digital engineering

- Use of parametric models to save construction time

- Simulation-based design and construction

HYDRAULIC DRIVES

TOOL SPINDLE POSITION-CORRECTION PROJECT

Machining centers for metal cutting processes require maximum precision and efficiency in sometimes less than ideal environmental conditions.

LCM SOLUTION

- New development of a digital hydraulic micro-positioning of tool spindles including a calibration device.

- Construction of a prototype that can be tested under real-world conditions

- Assistance with the transfer of the prototype into series production Ongoing further

- Development and optimization in coordination with the customer

MODELING AND SIMULATION

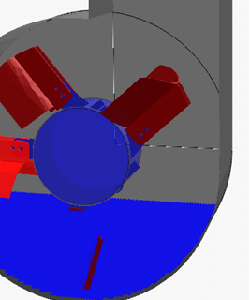

SNOW BLOWER / CHIPPER PROJECT

Snow blowers are conveyors optimized for their specific use. When snow blowers are further developed for use as wood chip conveyors, there are numerous problems that are not easily solved with conventional machine designs.

LCM SOLUTION

- Creation of a mechanical simulation model for the conveyor unit and coupling with the material models for the conveying media snow and wood chips

- Training of the customer in how to operate and evaluate the simulation model

VIBRATION TECHNOLOGY

AUTOMOTIVE VIBRATION DAMPING PROJECT

Above all for passenger vehicles, the comfort in the interior is very important.

LCM SOLUTION

- Analysis and simulation

- Customized design of controls, actuators, and power electronics

- Production and commissioning of a prototype active damping system

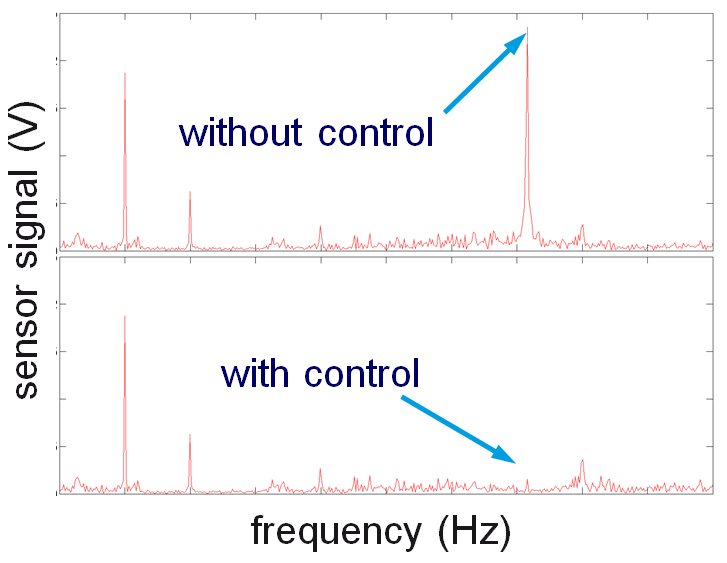

VIBRATION TECHNOLOGY

VIBRATION DAMPING HOUSEHOLD APPLIANCES

Noise in household appliances can be a nuisance. But sometimes it is not enough to alter the design or implement passive damping.

LCM SOLUTION

- Selection and positioning of suitable actuators based on measurements and simulation-supported analyzes

- Optimal control concept for active vibration damping for a single but variable frequency

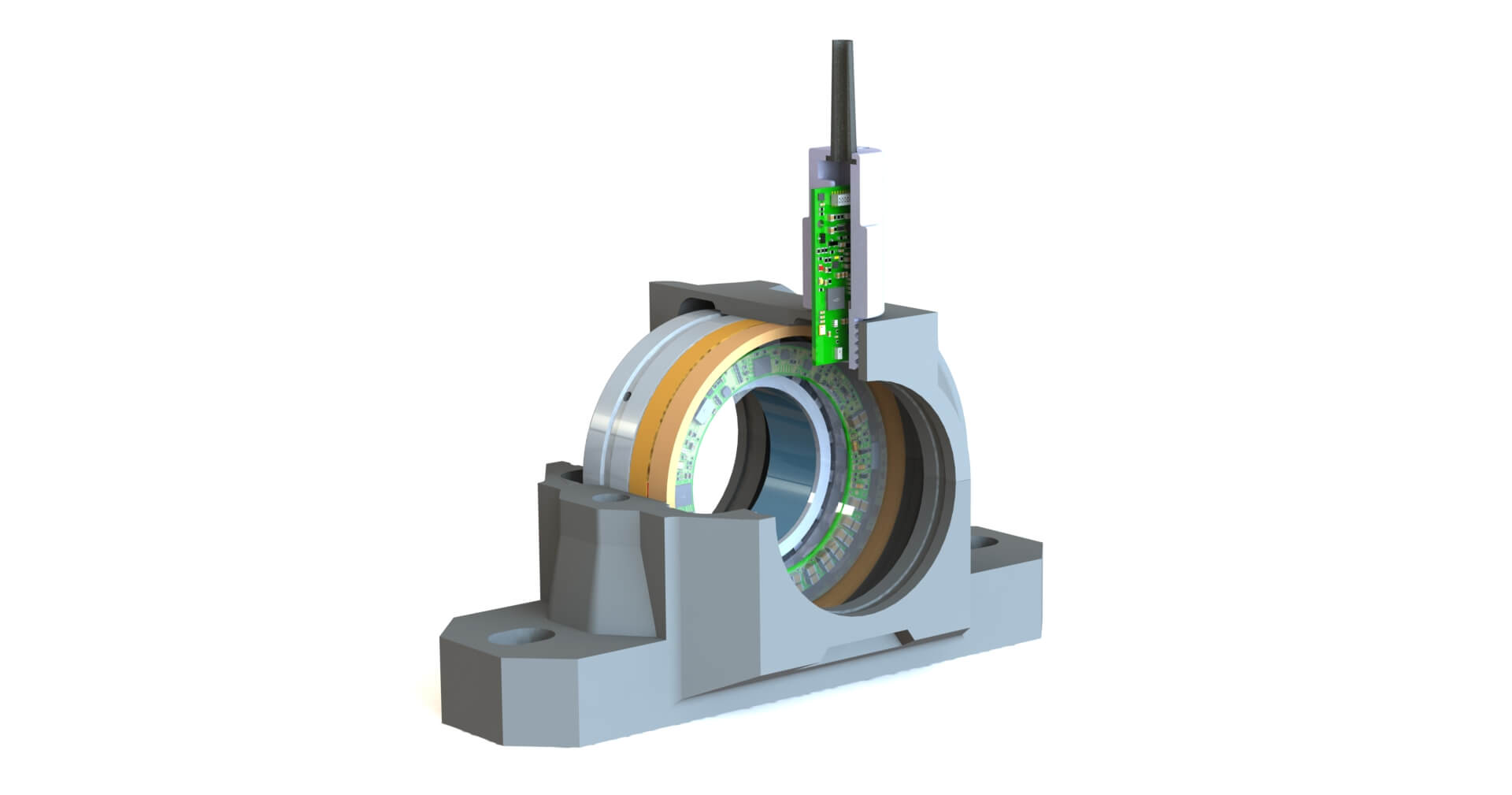

Industrial IoT

MoSS – Modular Sensor System

Rolling bearings are important machine elements which are often decisive for plant failure or trouble-free operation. Thus it is crucial to enable a continous monitoring of relevant parameters such as temperature, speed, etc. directly at the rolling bearing.

LCM Solution

- Development of the specification from the customer’s idea

- Development of a sensor system for measuring and logging a bearing rolling’s data with self-sufficient energy supply and wireless transmission

- Integration of different technologies into a complete system

- Construction of a test series and execution of performance tests

- Customer support during the implementation of a series production

TESTIMONIALS FROM OUR PARTNERS AND CUSTOMERS …

WE FIND THE RIGHT SOLUTION

Our projects bridge science and industry for the purpose of finding the right solutions for our customers. Our services also include in-house developments that can later be used in a wide variety of industries.

More of our solutions, projects, and prototypes can be found here:

COMPANY PARTNERS

We see our customers as partners with whom we maintain long-term cooperations and solve challenging tasks along the entire innovation chain.

BUSINESS NETWORKS

As a member of various economic networks, we act in a cross-industry and sustainable manner in order to help develop the latest technical innovations.

The regional and supra-regional networking helps us to stay up to date with the latest technical, economic and social developments.

Awards and Nominations

We are pleased that our developments and our research work are nationally and internationally nominated and awarded. We can proudly look back on numerous recognitions over the past few years.

OUR CUSTOMERS & PARTNERS

We make research findings work in the real world on behalf of our customers. In doing so, we work across industries. Our customers get a tailor-made solution from a single source through the integration of all necessary technologies into one overall package.