The interconnection between the die and the output pins in integrated circuits is mostly established via thin wires with diameters of less than 70μm. For power devices, redundant wires are required, to guarantee the current carrying capability. Electrical tests are not able to detect the loss of single wires, which can lead to a shortened life of the component. In further consequence, we have successfully developed a new contactless measurement method, to detect such defects, based on measuring the magnetic field due to a current flow thru the interconnection.

Power electronic components are able to handle voltages and currents in the range of kV and kA. Especially, the electrical interconnection between the die and the output pins is crucial in this context. For establishing the interconnection thin copper wires with a diameter of less than 70μm are used. Due to the small diameter redundant wires are needed, in order to guarantee the current capability of the device. In such a case, an electrical test is not able to detect the loss of single wires since the impact on electrical parameters is usually low. For improving the quality assurance process and subsequently the chip diagnostic of power electronic components, it is necessary to recognize defects resulting from an imperfect interconnection at an early stage. A current-carrying wire creates a magnetic field, so irregular connections can be detected by analyzing the magnetic field around a device during the electrical test.

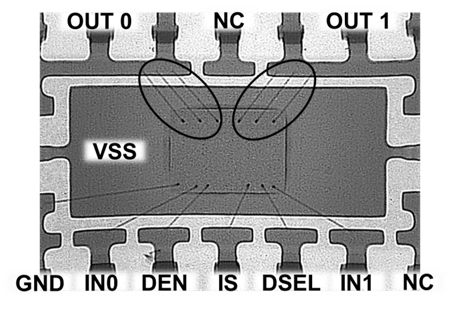

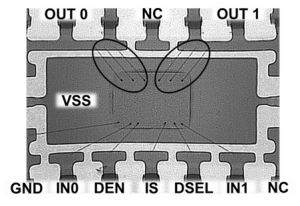

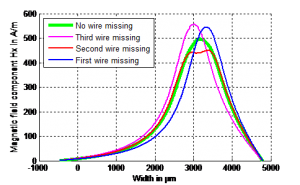

For proof of concept, we used the Power MOSFET chip BTS5120-2EKA from Infineon Technologies, a X-ray photography is shown in Fig.1. This chip possesses two independently switchable channels OUT0 and OUT1, each having a nominal current capability of up to 2.5A. For each channel three separate wires are used to connect the output pins with the die. To estimate the impact of missing wires on the magnetic field component HX above the chip an FEM (finite element method) simulation for OUT1 was done, shown in Fig.2. Depending on whether the first, second or third wire of OUT1 is missing, not only the maximum value of the field strength changes, but also its position shifts.

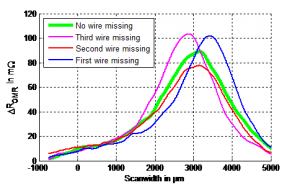

In order to identify defects, the magnetic field must be measured with a very high spatial resolution and then be compared with the measurement results of a non-defective probe. Therefore, a magnetic field sensor array based on the GMR (giant magnetoresistance) effect was designed in corporation with Infineon Technologies. In Fig. 3 the measured change in resistance ∆RGMR above the chip of a single GMR element is shown. The measured change in resistance, which results from the GMR effect, agrees very well with the simulated field profile. Accordingly, missing wires can be detected effectively by analyzing the magnetic field due to a current flow thru the interconnection.

Fig.1: X-ray photography of a Power MOSFET chip BTS5120-2EKA

Fig.2: FEM simulation results of the magn-etic field component Hx, 150µm above the chip package, for a current of 2A.

Fig.3: Measured change in resistance of a single GMR element, approximately 150µm above the test chips, for a current of 1A.

Impact and effects

We have introduced a new non-contact measurement method, which makes it possible to recognize electrical interconnection failures in power devices during the electrical testing. We utilized the magnetic field which is inherently produced during the electrical functional testing. Therefore, we have realized a GMR sensor array to measure the magnetic field with a high spatial resolution.

We have introduced a new non-contact measurement method, which makes it possible to recognize electrical interconnection failures in power devices during the electrical testing. We utilized the magnetic field which is inherently produced during the electrical functional testing. Therefore, we have realized a GMR sensor array to measure the magnetic field with a high spatial resolution.