VIRTUAL DEVELOPMENT

The concept of virtual development ranges from the development stage through the commissioning phase to the continuous operation of machines, plants and processes. The idea is to support each phase of the full lifecycle by an appropriate representation in the virtual world (models, simulation).

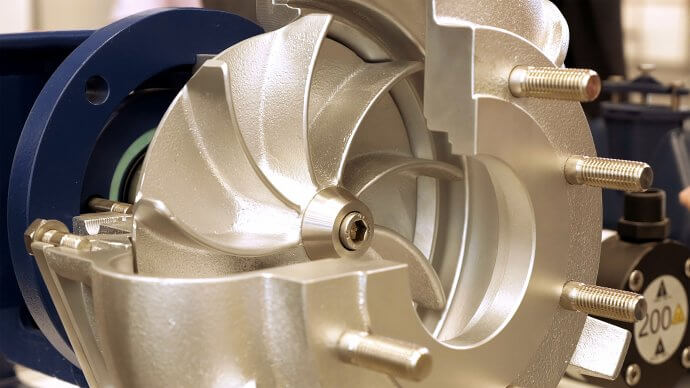

Virtual Prototype

The development and optimization of a product or process is supported by detailed simulation models. This reduces the number of real prototypes and the scope of experimental tests and trials, thus reducing development time and costs.

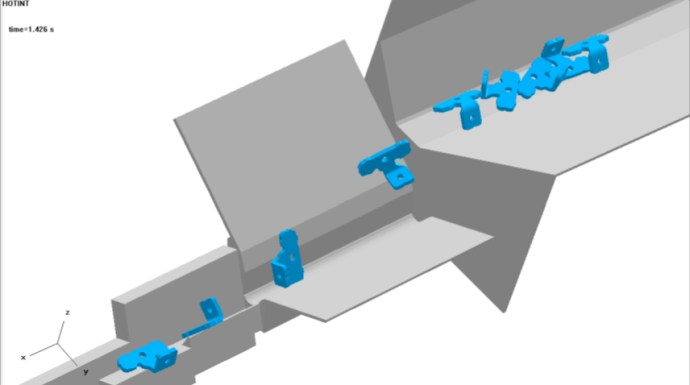

Virtual Commissioning

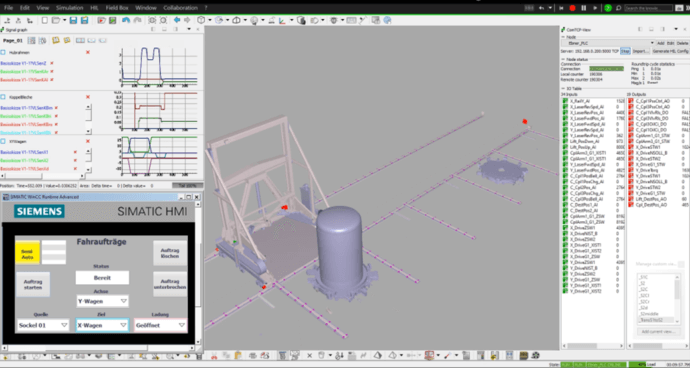

Modern virtual commissioning software allows generating virtual representations of plants or machines from the CAD models in a few simple steps. With the connection of the real automation system to this virtual world, tests and optimizations can be carried out on the sequence control in advance without risk, thus shortening the real commissioning phase.

Digital Twin

By digital twin we mean efficient simulation models that run online as virtual representations in parallel to real machines, plants or processes during continuous operation. While passive digital twins provide additional data or information about the running process or system state, the active digital twin affects the real process and thus enables online optimization and adaption.

Condition Monitoring & Predictive Maintenance

Models can not only give a detailed picture of the current situation, but also provide a preview of the future. The objective is a better monitoring of the actual state of machines or processes, making predictions and reacting before damage or problems occur.

OUR SERVICE OFFER

Knowledge transfer

We offer you a wide range of possibilities to build up your competencies, to advise you on the best solution strategy or to give you an overview of the current state of the art – from presentations or webinars to training courses and workshops, flexible and individually plannable.

Development

We develop for you from the first idea to the finished prototype.

Especially in case of resource bottlenecks in your own development team or if technological knowledge is necessary that is not available in the company, we offer you to carry out the complete R&D project from the idea to the prototype.

Co-Development

We do R&D together with your development department.

As input for new solution strategies, in case of personnel bottlenecks or if competence building in your own development team is required, we offer you the opportunity to carry out subtasks or work packages together with us.

Modeling and Simulation

We provide a deeper insight.

The basis for virtual development is a suitable model. The required level of detail results from the object of investigation, whereby many insights only become visible through cross-domain considerations. Feasibility study or detailed simulation, coupling of different simulation tools or 3D simulation environment with real automation hardware – we offer extensive know-how in a comprehensive way.

OPTIMIZATION

We find optimal solutions for engineering and continuous operation.

Finding the right solution under consideration of a variety of optimization criteria and constraints is a big challenge for complex systems. The right software and a systematic approach help us with this task. Optimization has to be considered through the entire product life cycle even during continuous operation. Digital twins, condition monitoring and predictive maintenance represent promising potentials for after-sales services.

APPLICATIONS & BRANCH OF INDUSTRY

ADDITIONAL INFORMATION: LINKS & DOWNLOADS

REFERENCE & REPORTS

EUH4D – Fund data-driven products and services

Fund your innovative data driven products or services60.000 € FINANCIAL CONTRIBUTION PER BENEFICIARY+ 70.000 € DIH SUPPORT VALUE PER EXPERIMENT9. NOV. 2022 APPLICATION DEADLINE2023 FEBRUARY START OF EXPERIMENTS9 MONTH DURATIONCalling on SMEs, start-ups, and web...

Efficient testing with UFOs

(Semi-) autonomous vehicles present new challenges to the currently valid procedures for tests during development, but also to the test procedures for approval. In order to prove the safety of the many (partially) autonomous systems that interfere with the driving...

LCM with outdoor TV studio at Hanover Fair: “Twin Space” fuses real machines with digital ones

Linz, Ennsdorf, Hanover, June 2018 - At this year's Hanover Fair, Linz Center of Mechatronics GmbH (LCM) turned the Salvagnini plant in Ennsdorf into a kind of outdoor TV studio. From there, impressive pictures from the interior of the latest generation of automatic...