Measurement with 3D profilometer. Stops and positioning aids realized with 3D printing or magnets.

Requirements

- Verification of the required surface roughness of purchased parts from different suppliers.

- Determination of the value Rz according to ISO 4288, e.g. Rz < 100µm

- Additional determination of the surface roughness Sa (average height/roughness) and Sz (maximum height/roughness)

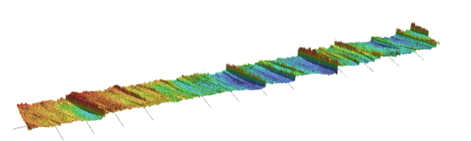

- Images of the scanned depth profiles from different views

- Large number of measurements to cover all product variants

Solution

- Measurements with Keyence 3D profilometer

- Automated calculation of the values Rz, Sa and Sz

- Accurate documentation of the measurements and presentation of the results in a report

Surface scan (difference between red and blue: 0.15mm)