Under LCM’s leadership, LCM, AISEMO, TCKT and five injection moulding companies cooperated in the cluster project “ReGuMa” to reduce machine downtime in injection moulding. Wireless sensors record the vibrations of the machines. The evaluation of...

Jan 19, 2023 | cost reduction, Digitization, General@en, IIoT, Industry 4.0, networked, digital systems, predictive analytics, research, sensing systems, smart factory

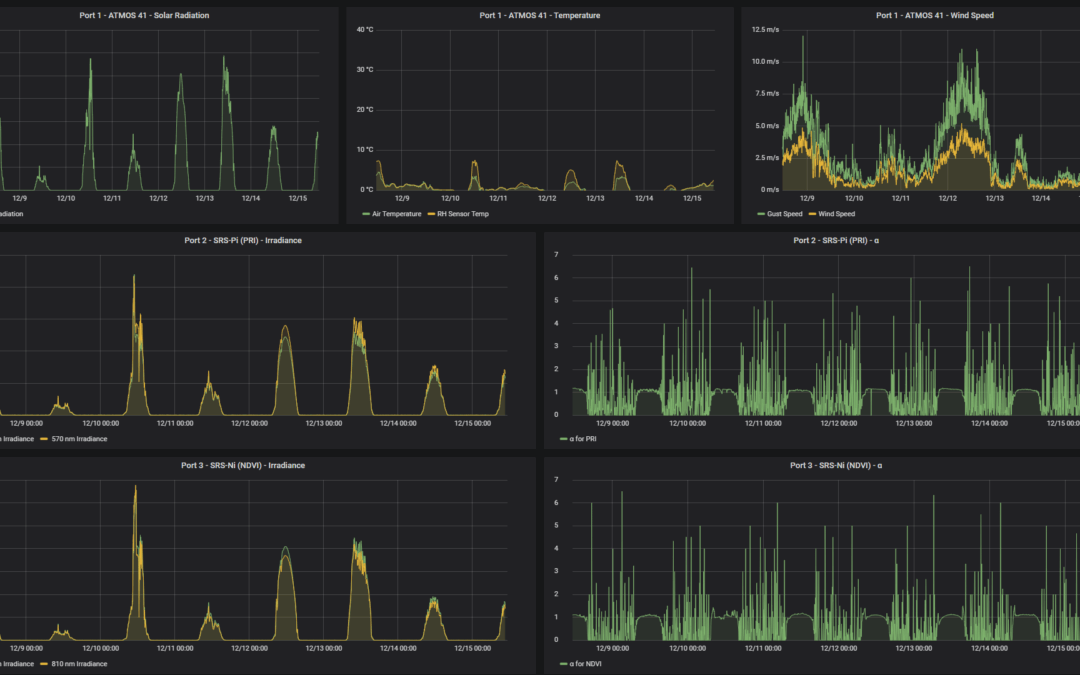

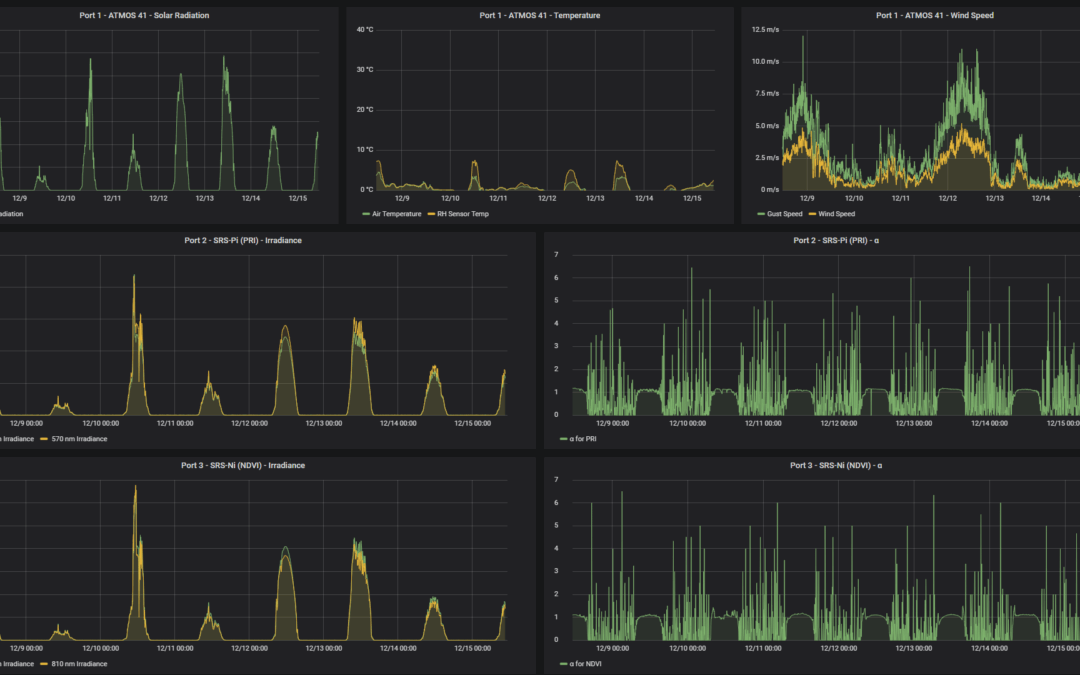

Within the EU-funded project Transfarm 4.0, in spring 2021, LCM has equipped a vineyard in Tata, Hungary, with a sensor and data logging system. This system is measuring more than 100 vegetation and climate-related parameters. The data resulting from the 32 sensors...

Dec 16, 2021 | Digitization, General@en, IIoT, Industry 4.0, National and international research projects, sensing systems

The largest IEEE conference on communication in industrial automation systems, WFCS 2021 (Int. Conference on Factory Communication Systems) will take place in Linz this year and will be co-organized by the LCM. Communication in production facilities is currently...

Feb 26, 2021 | General@en, IIoT, Industry 4.0

The European Commission is funding a 29 partners from 12 countries consortium within the H2020 framework program with €26 million, which is promoting the development and demonstration of driverless heavy-duty vehicles under rough weather conditions. The consortium of...

Jan 25, 2021 | autonomous systems, Digitization, General@en, Industry 4.0, localization, localization systems and tracking, smart factory

The effects of climate change do not stop at the borders of vineyards. Unsteady rainfall affects the yield and the quality of the grapes and the wine. Thus, the diverse needs of different types of grapes demand the utilization of irrigation systems. In order to be...

Dec 9, 2020 | Digitization, General@en, Industry 4.0, National and international research projects, News@en, smart factory

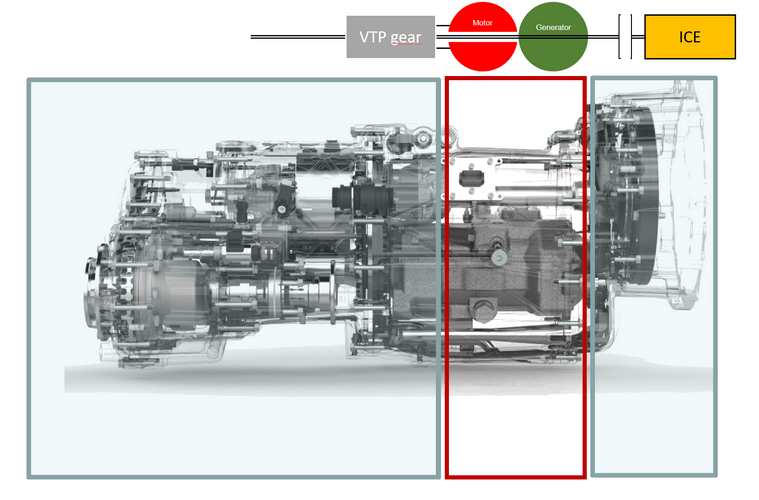

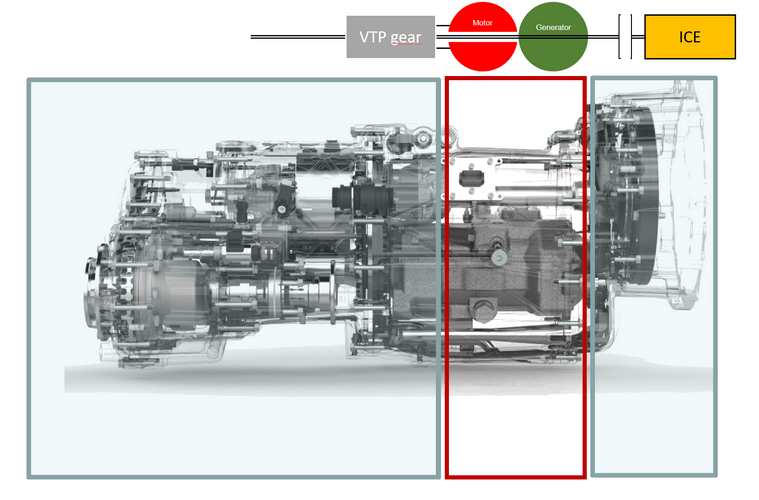

Within a company consortium, LCM and its partners are developing an electric variator for an emission-reduced continuously variable transmission (CVT). The aim of the project is the replacement of the current standard hydraulic variator unit with two electric machines...

Nov 29, 2019 | electrical drives, General@en, Industry 4.0, National and international research projects, research