Within a company consortium, LCM and its partners are developing an electric variator for an emission-reduced continuously variable transmission (CVT). The aim of the project is the replacement of the current standard hydraulic variator unit with two electric machines which significantly reduces pollutant and noise emissions from municipal and emergency vehicles.

Pollutant and noise emissions do not only affect individual traffic, but also municipal and emergency vehicles must be optimized accordingly. Agricultural machines are often operated with a continuously variable transmission, because the vehicle speed can be controlled independently of the speed of the internal combustion engines (ICE). For example, the deployment of a vehicle with high power requirements for the power takeoff can be operated at a high VKM speed, while at the same time, the vehicle speed is optimally adjusted to the respective work process.

However, these continuously variable transmissions are characterized by high losses and therefore, high emission values of the internal combustion engines, especially in the partial load range.

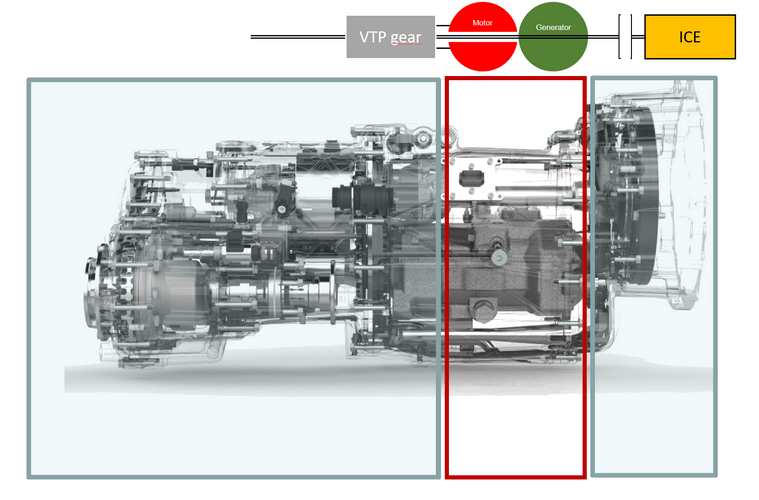

The aim of the project is to replace the hydraulic variator units in the design of the transmission specialist VDS Getriebe GmbH with electric machines. Two highly compact, innovative and cost-effective electric drives will be used in generator and engine operation. The drives will be designed, simulated and optimized by Linz Center of Mechatronics GmbH and will be built together with Miba Sinter Austria GmbH. By connecting the VKM with the electrical machines and a battery storage unit, downsizing of the VKM can be achieved.

All components are specifically developed, manufactured and assembled. In order to ensure the cooling of the electrical units, LKR Ranshofen GmbH is also developing a housing with an innovative cooling system. In addition to a functional test of the individual components, their suitability is verified by simulating the applications in a reference vehicle of Reform-Werke.

After the assembly, the components are tested on the test bench and in a test vehicle to enable comprehensive evaluation of hardware and complex control systems.

The expected results of this research project include a reduction of fuel consumption and thus of pollutant emissions as well as reduced or minimal acoustic emissions in battery and electric hybrid operation while unchanging the vehicle performance.

Project data:

– Project start: 07/2019

– Duration: 30 months

– Sponsor: FFG

– Coordinator: LKR Leichtmetallkompetenzzentrum Ranshofen GmbH

– LCM project partners:

Bitter GmbH

Miba Sinter Austria GmbH

Reform-Werke Bauer and Co GmbH

VDS Transmission GmbH

Voltlabor GmbH

Further information about the project can be found under:

https://www.ait.ac.at/themen/casting-technologies/projekte/ecvt/