Small Parts Assembly

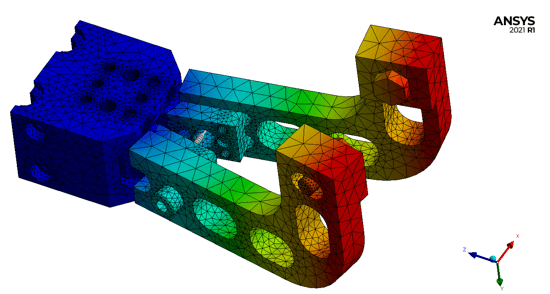

High Speed Gripper

Photo: STIWA Automation GmbH.

Parts and machine components are assembled at top speed on STIWA’s systems.

The custom-made grippers with which the parts are gripped and moved are important components. The grippers must be as small and light as possible to enable high speeds. At the same time, however, they must be sufficiently robust to withstand continuous stress without damage in series production. This is a constant balancing act, which in the worst case can lead to production downtimes.

Previously, the grippers therefore had to be tested in elaborate continuous load tests before they could be used in production. Together with LCM, it was shown that these strength tests can be carried out significantly faster (and without building prototypes) using simulations.

Requirements

- Analysis of mechanics and strength

- Assessment of mechanical strength before long-term test

- Reduction of material costs and test time

- Identification of potential vulnerabilities

Solution

- Transient mechanical simulation (finite elements, geometric nonlinear)

- Standardized strength evaluation based on FKM guidelines (stress evaluation)