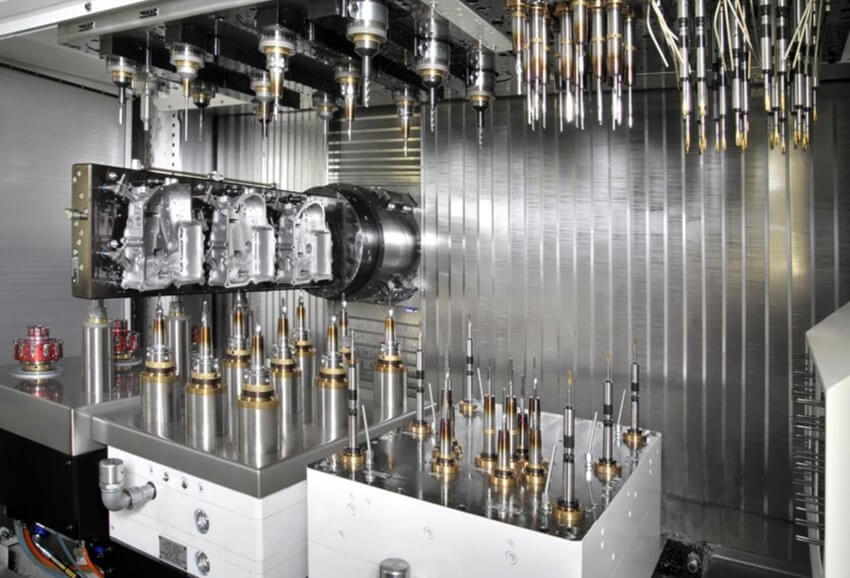

Micropositioning of Machine Tool Spindles

Highly accurate and robust positioning of spindles

In order to increase throughput, parts are machined in parallel with double or triple spindles. To compensate for deviations (position errors, etc.), the spindles are equipped with micropositioning units that can correct the positions of the spindles relative to each other.

This considerably reduces the maintenance effort of such machines.

Project partner: Anger

Requirements

- Actuator development (X,Y,Z – Axes)

- Precision < 1 µm

- High positioning speed

- High robustness

- High stiffness

- Sensorintegration

Solution

- Spindle positioning at the tool machine

- High precision cylinder positioning

- Calibration device

- Use of standard components