Measurement with the 3D profilometer before use

Requirements

- High-precision measurement of the cutting geometry

- Comparison of measurements before and after use in the machine

- Measurement from different views

- Objective (numerical) measurement of wear

- Flexible project handling and billing according to the number of measured components

Solution

- Measurement with 3D profilometer

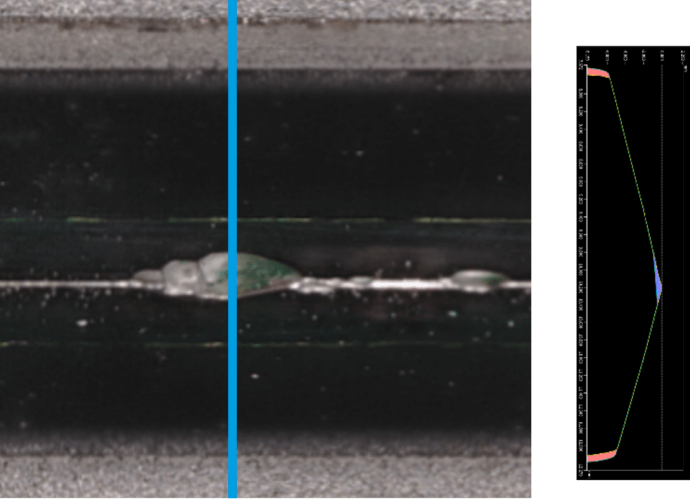

- Graphical representation of the contour line

- Numerical evaluation of the wear (difference volume) in mm³

Photo and measurement result of the profile line after use. In blue the changes in geometry due to wear.