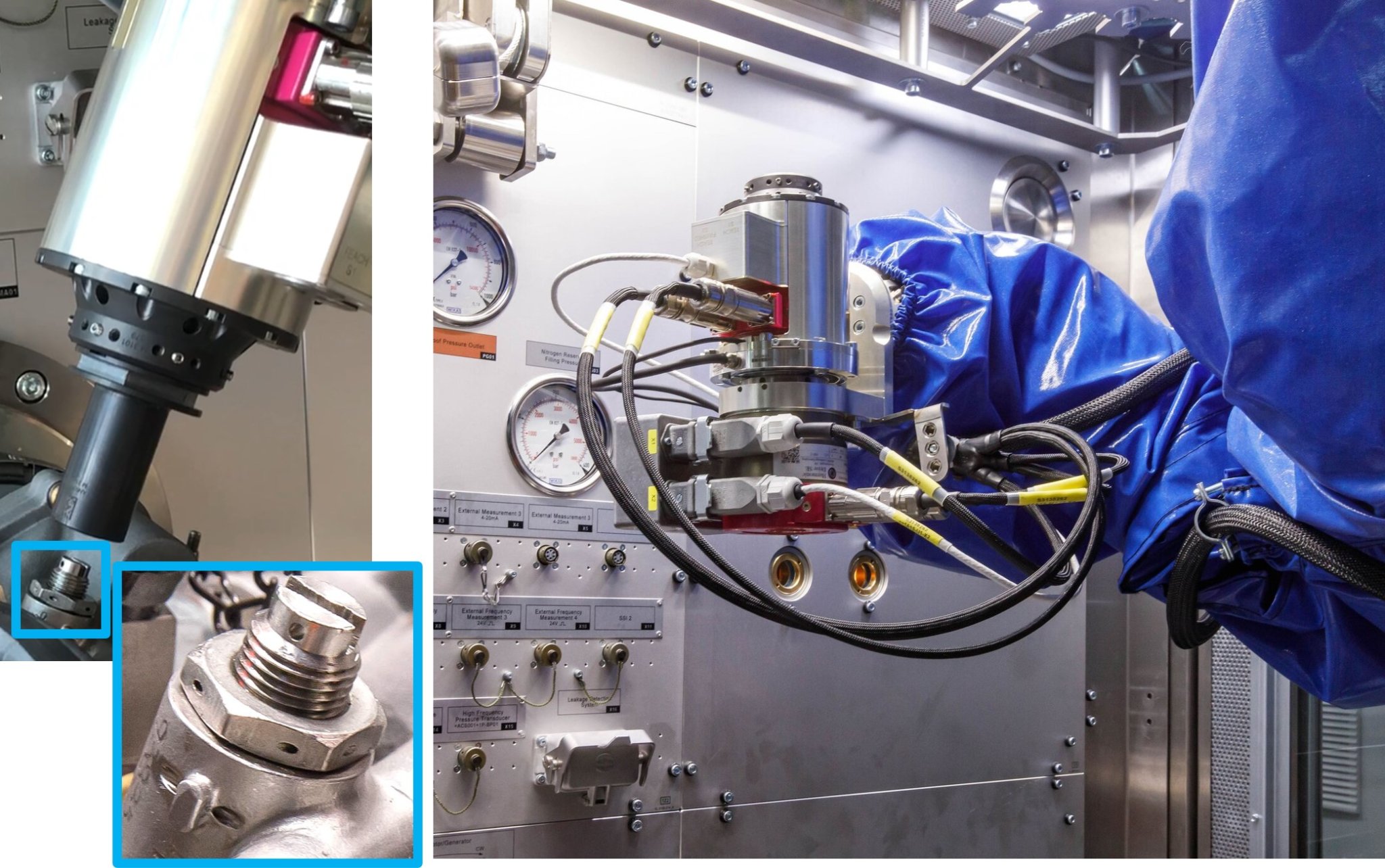

Customized screwing and adjustment unit

In a project with the company Testfuchs, a robot tool was developed that enables the automation of pump test benches. There was no available solution on the market for loosening and tightening lock nuts and fine adjustment of adjusting screws in a large number of variants.

LCM has created a tool with integrated sensors and actuators that perfectly meets the requirements in terms of available installation space, required torques and accuracy.

Goals and methods

- Increasing the efficiency of test benches for hydraulic aircraft components

- Reduction in employee stress (noise and stress)

- Reduction in employee stress (noise and stress)

- Sensor and actuator integration for confined spaces

- Integration into existing test bench design and existing test sequences

Solution and benefits

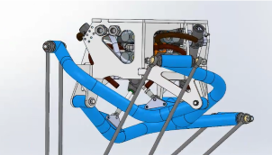

- Robot-based screwdriving unit with harmonic drives and force/torque sensors

- Design and optimization with digital product development (system engineering)

- Data monitoring for automatic test protocol generation

- Supporting the customer in the integration and implementation of application tests and creation of a prototype

Success Story “100% AUTOMATION

through customized system design”

Dipl.-Ing., Dr. Markus Schörgenhumer, BSc

Business Area Manager Mechanics & Control

Our reference projects

Robotics in the agricultural sector

Use of robotics in the agricultural sector Simulation, optimization and prototyping The agriculture of the future needs efficient, autonomous solutions…

Robot for pipe inspection

Robot for pipe inspection Autonomous inspection of tunnel drainage pipes Together with ÖBB-Infrastruktur AG, LCM GmbH is developing the Tunnel…

Autonomous waste disposal and sorting

Waste robots in public spaces LCM is working together with the company Brantner on an autonomous robot system that automatically…