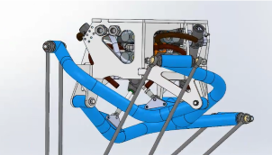

High-speed motor for compressor systems

A head start through optimization

Fuel cell technology is one of the key technologies of the future. Electricity can be generated from hydrogen and oxygen. This process requires a constant supply of air, which is provided by high-speed compressor systems.

Together with Pankl Turbosystems, LCM is developing very compact, high-speed drives for compressor systems for the air supply of fuel cells. The drive systems can also be used in electrically assisted turbochargers with just a few adaptations.

For high-speed drives, the electromagnetic design is not the only decisive factor. To develop an optimized overall system, strength, rotor dynamics, fluid dynamics and cooling must also be taken into account. The LCM development tool SyMSpace makes it possible to combine these different aspects in one model and optimize them holistically.

Requirements

- Use for high-performance fuel cells or electrically assisted turbochargers

- Very compact design

- Speeds of up to 150,000 rpm

- Power range 15 – 86kW

- Voltage range 48 – 800V

- Minimum development time to functional model

Your benefit

- Shorter development time

- Simple design changes

- Fewer prototypes required

- Lower trial costs

Hubert Mitterhofer

Business Area Manager Electric Drives

Further reference projects

Smart Pump Management Die casting machine/Bühler

Less wear, more efficiency: retrofit solution for die casting systems during operation Smart pump management optimizes hydraulic systems in Bühler…

Synchronized oscillation for higher compaction quality

Increasing the compaction quality of road rollers Digital hydraulic solution optimizes drum synchronization in road construction In cooperation with Hamm…

Robotics in the agricultural sector

Use of robotics in the agricultural sector Simulation, optimization and prototyping The agriculture of the future needs efficient, autonomous solutions…