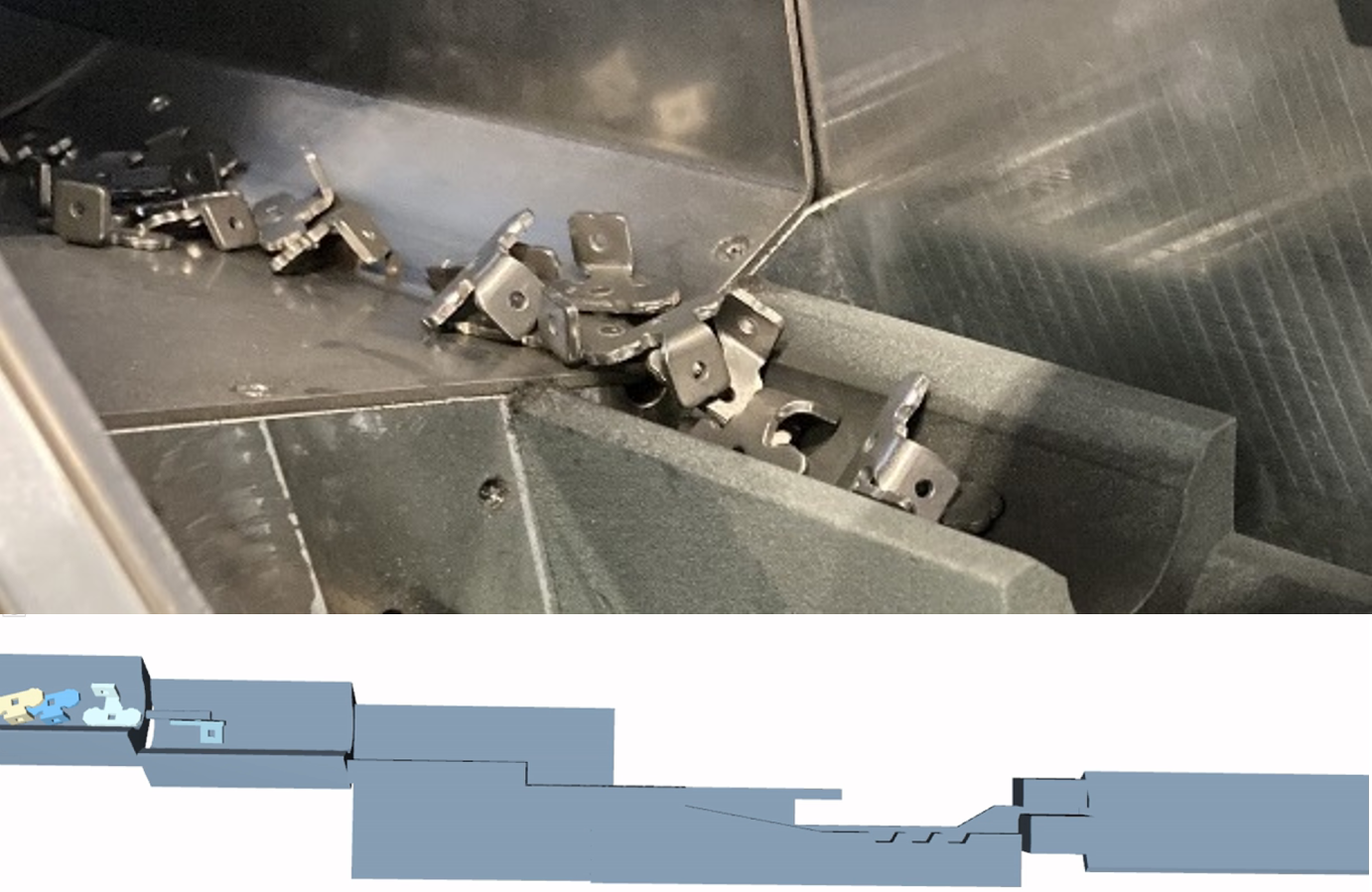

Virtual prototype

Optimum machine design for feeding and sorting systems

Vibratory conveyor systems are an important component of modern automation systems. Competitive systems require optimum conveying performance by optimizing the baffle geometry. A software tool developed for STIWA Automation GmbH for the design of vibratory conveyor systems has been integrated into the company and is actively used in the manufacturing process.

Requirements

- Separated bulk parts with defined orientation

- Prediction of the appropriate baffle geometry for the desired conveying behavior

Your benefit

- Savings in prototype construction

- Savings in development costs

- Higher process performance

Dipl.-Ing., Dr. Markus Schörgenhumer, BSc

Business Area Manager Mechanics & Control

Further reference projects

Automated measuring processes using cobots

Automated measuring processes using cobots Seamless combination of robotics and measurement technology A fully automated measurement process combines precise positioning,…

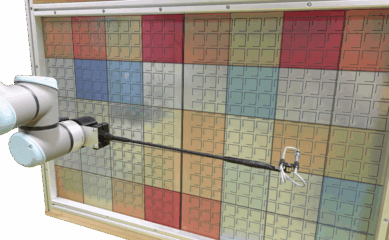

Automated sound intensity measurement

Automated sound intensity measurement Precise evaluation using sound pressure, sound intensity and sound power The system can be used to…

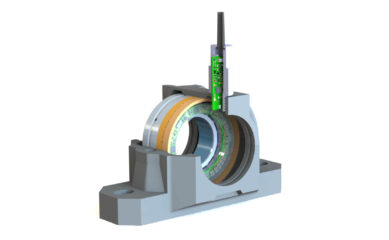

Self-sufficient sensor technology for rolling bearings

Self-sufficient sensor technology for rolling bearings Maintenance-free, wireless data acquisition Together with NKE Bearings, LCM has developed a technology that…