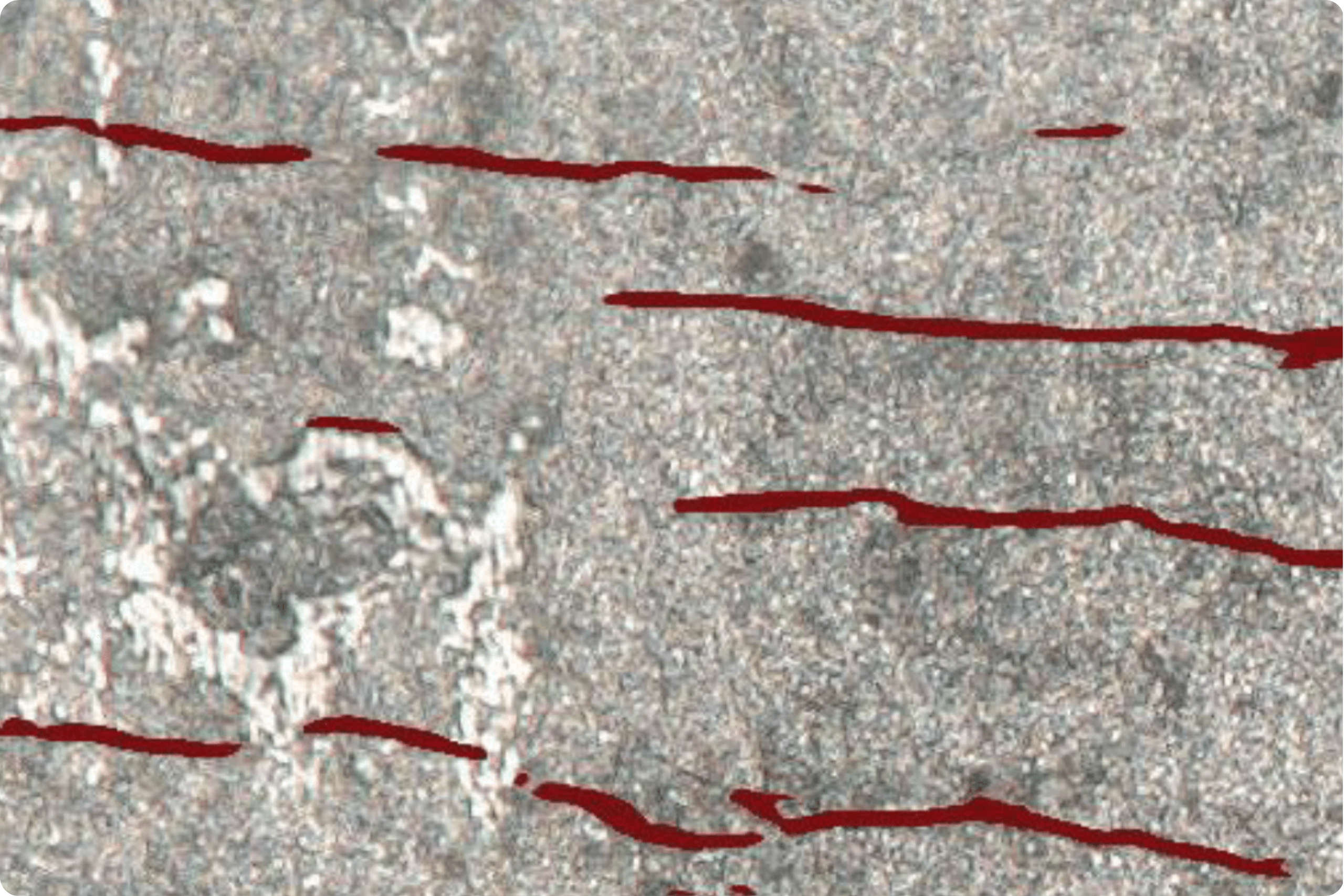

Measurement of hairline cracks using deep learning

Image-based quality assurance

Cracks are to be detected and measured on steel strips with a large data volume of 400 microscope images per sample. The cracks in the image are very thin, approximately 1 pixel wide. In addition, artifacts make crack detection difficult, which is why conventional image processing methods do not offer an exact and robust solution.

Sabrina Fleischanderl et al, “CNN-based crack detection in oxide layers of hot rolled steel sheet samples for the validation of a pickling process model”, Proc. 3rd Symp. on Pattern Recognition and Applications, 2022.

Project requirements

- Cracks should not only be detected, but also measured (density, vertical distance in the image)

- Large amount of data (400 microscope images per sample)

- The cracks are very thin in the image (width ~ 1 px), and other artifacts make crack detection more difficult

- Classic image processing cannot provide an exact and robust solution

The solution

- Precise and stable segmentation of cracks with neural network (UNET)

- 60 images were annotated by hand

- Wireless connection of each measuring point to the relay station

- In addition, a freely available annotated data set (ISBI 2012 Challenge, cell membrane data) was used for training

- Precise solution with minimal effort

Erwin Schimbäck

Business Area Manager Sensors & Communication

Further reference projects

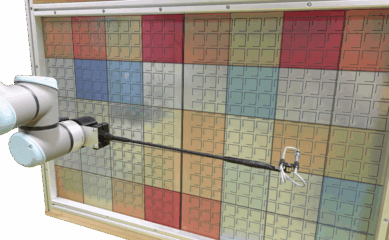

Automated measuring processes using cobots

Automated measuring processes using cobots Seamless combination of robotics and measurement technology A fully automated measurement process combines precise positioning,…

Automated sound intensity measurement

Automated sound intensity measurement Precise evaluation using sound pressure, sound intensity and sound power The system can be used to…

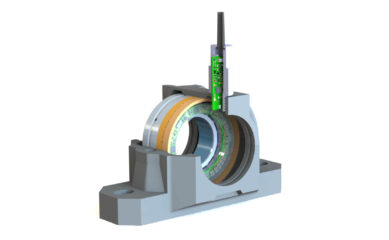

Self-sufficient sensor technology for rolling bearings

Self-sufficient sensor technology for rolling bearings Maintenance-free, wireless data acquisition Together with NKE Bearings, LCM has developed a technology that…