Increasing the compaction quality of road rollers

Digital hydraulic solution optimizes drum synchronization in road construction

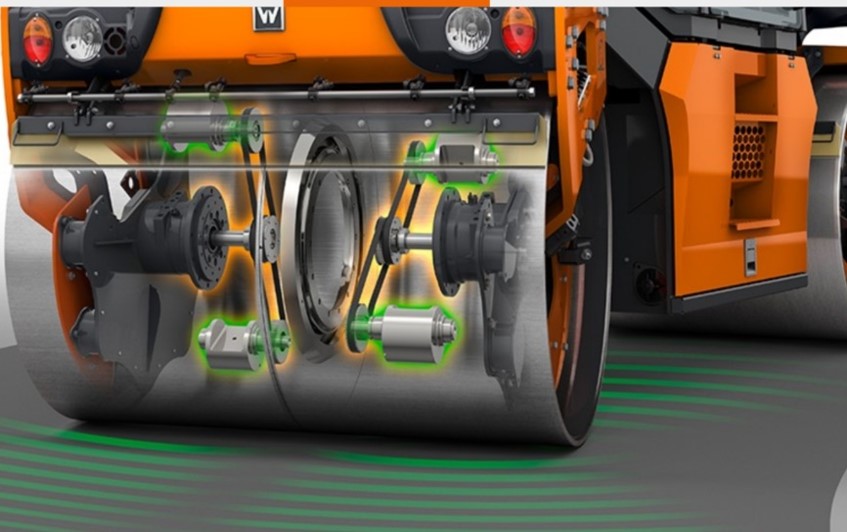

In cooperation with Hamm AG, LCM developed a digital-hydraulic solution for the precise synchronization of split oscillating drums for road rollers. The aim was to increase the compaction quality through in-phase oscillation of the drums and at the same time reduce the strain on man and machine. At the heart of the system is an innovative, digitally controlled drive circuit that guarantees uniform oscillation through precise control of the hydraulic motors – even when cornering or under changing loads.

Requirements

- Synchronization of two hydraulic motors by specially diverting part of the volume flow

- Precise dosing from 0.05 l/min to 10 l/min at a pressure of up to 450 bar

- Hardware (valves and electronics) and software for closed-loop control realized with an existing mobile control unit

Your benefit

- Energy-efficient digital hydraulics solution for this application

- Special IIR filtering of the sensor signals to generate a suitable target signal for control

- NEW control strategy with the mobile control unit

- Customized coil design

Bernd Winkler

Business Area Manager Hydraulic Drives

Further reference projects

Smart Pump Management Die casting machine/Bühler

Less wear, more efficiency: retrofit solution for die casting systems during operation Smart pump management optimizes hydraulic systems in Bühler…

Synchronized oscillation for higher compaction quality

Increasing the compaction quality of road rollers Digital hydraulic solution optimizes drum synchronization in road construction In cooperation with Hamm…