Energy optimization composite presses

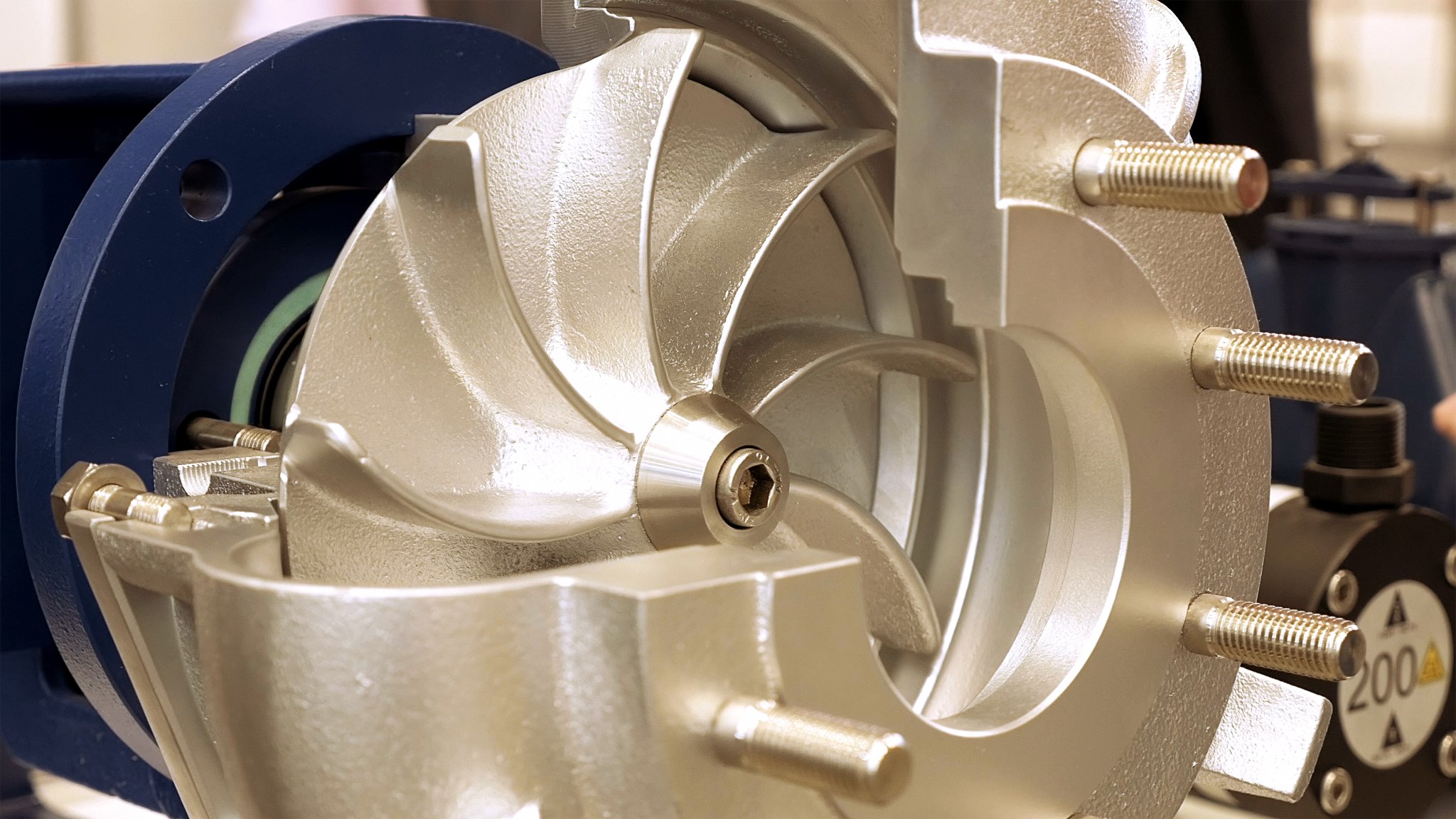

Customized turbomachines

Customized turbomachinery requires the interaction of several specialist domains in design and development. While a classic design approach is sufficient in simple cases, it quickly reaches its limits when it comes to more demanding requirements. For example, to achieve an optimized overall system, a holistic approach is recommended that optimizes all relevant sub-aspects while taking mutual dependencies into account:

- Fluid dynamics

- Electromagnetic drive

- Strength and rotor dynamics

- Thermal design and cooling

- Vibrations and acoustics

The SyMSpace development tool allows several of these areas to be optimized as a whole.

Requirements

- High efficiency and low operating costs

- Compact design with high power density, speed and dynamics

- Customized, integrated electric drive

- Oil-free and wear-free bearings

- Minimized vibrations and noise

Your benefit

- Ultra-high-speed permanent magnet synchronous motor

- Power electronics

- Maximum degree of optimization in the design (SyMSpace)

- Close cooperation with the development department

Hubert Mitterhofer

Business Area Manager Electric Drives

Further reference projects

Multifunctional milling machine

Discover how customized functional steels improve the properties of sheet steel and open up new application possibilities.

Analysis of vibrations in pipeline networks

Analysis of vibrations in pipeline networks Piping networks are subject to complex interactions with hydraulic and mechanical components – such…

Adjustable passive vibration damper

Adjustable passive vibration damper Effective vibration reduction for buildings Buildings are exposed to a variety of loads, for example from…