Measurement of hydraulic systems

Precise measuring systems for hydraulic components in research and industry

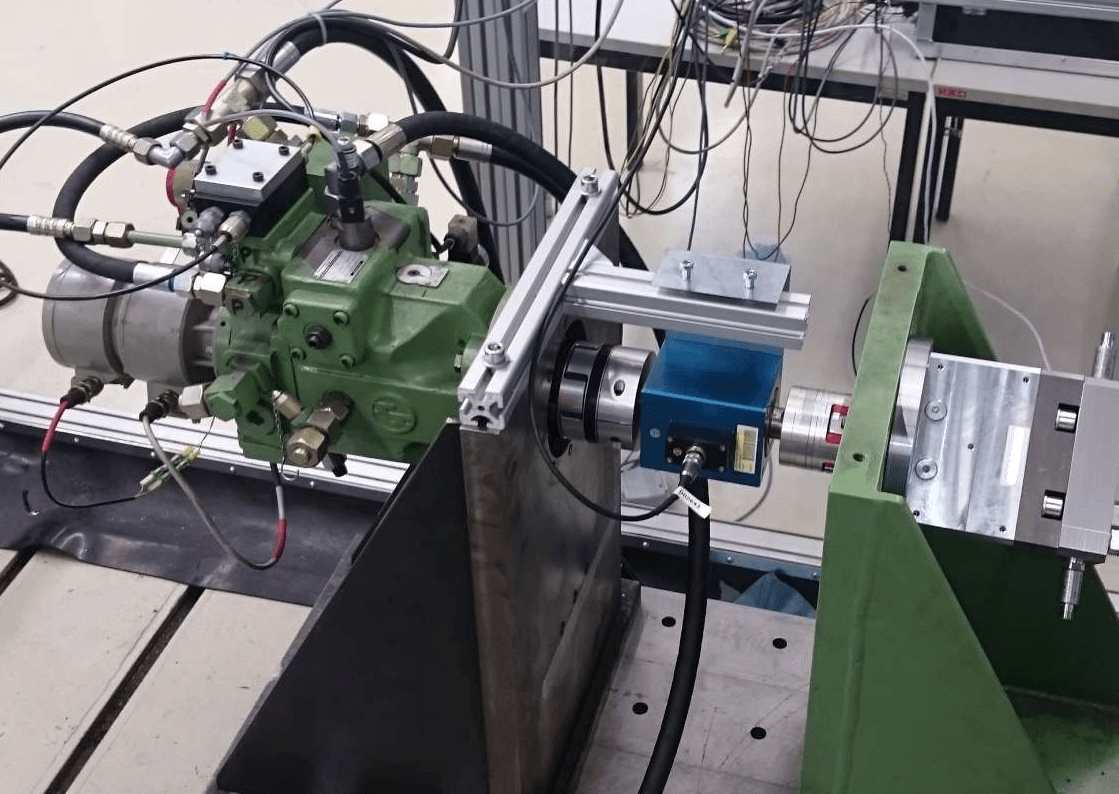

The focus is on the development of innovative measuring systems for hydraulic components, including pumps, cylinders and valves. State-of-the-art technology is used to record parameters such as torque, pressure, volume flow and efficiency in order to optimize efficiency and service life. The solutions are used in research and industry – wherever maximum precision is required.

Requirements

- Pump measurement

- Cylinder measurement

- Valve measurement

- Magnetic measurement

- Efficiency, leakages, friction, wear, maps, etc.

Solutions

- Hydraulic motors, pumps, cylinders

- Hydraulic supply up to 2 x 50kW, 200 L/min, 300 bar

- Torque/speed/force measurement

- Pressure/volume flow measurement (50mL/min to 600L/min)

- Gearboxes, flanges, clamping fields

- Magnet development

Bernd Winkler

Business Area Manager Hydraulic Drives

Further reference projects

Multifunctional milling machine

Discover how customized functional steels improve the properties of sheet steel and open up new application possibilities.

Analysis of vibrations in pipeline networks

Analysis of vibrations in pipeline networks Piping networks are subject to complex interactions with hydraulic and mechanical components – such…

Adjustable passive vibration damper

Adjustable passive vibration damper Effective vibration reduction for buildings Buildings are exposed to a variety of loads, for example from…