Early fault detection for all injection molding machines

Reduction of machine downtimes

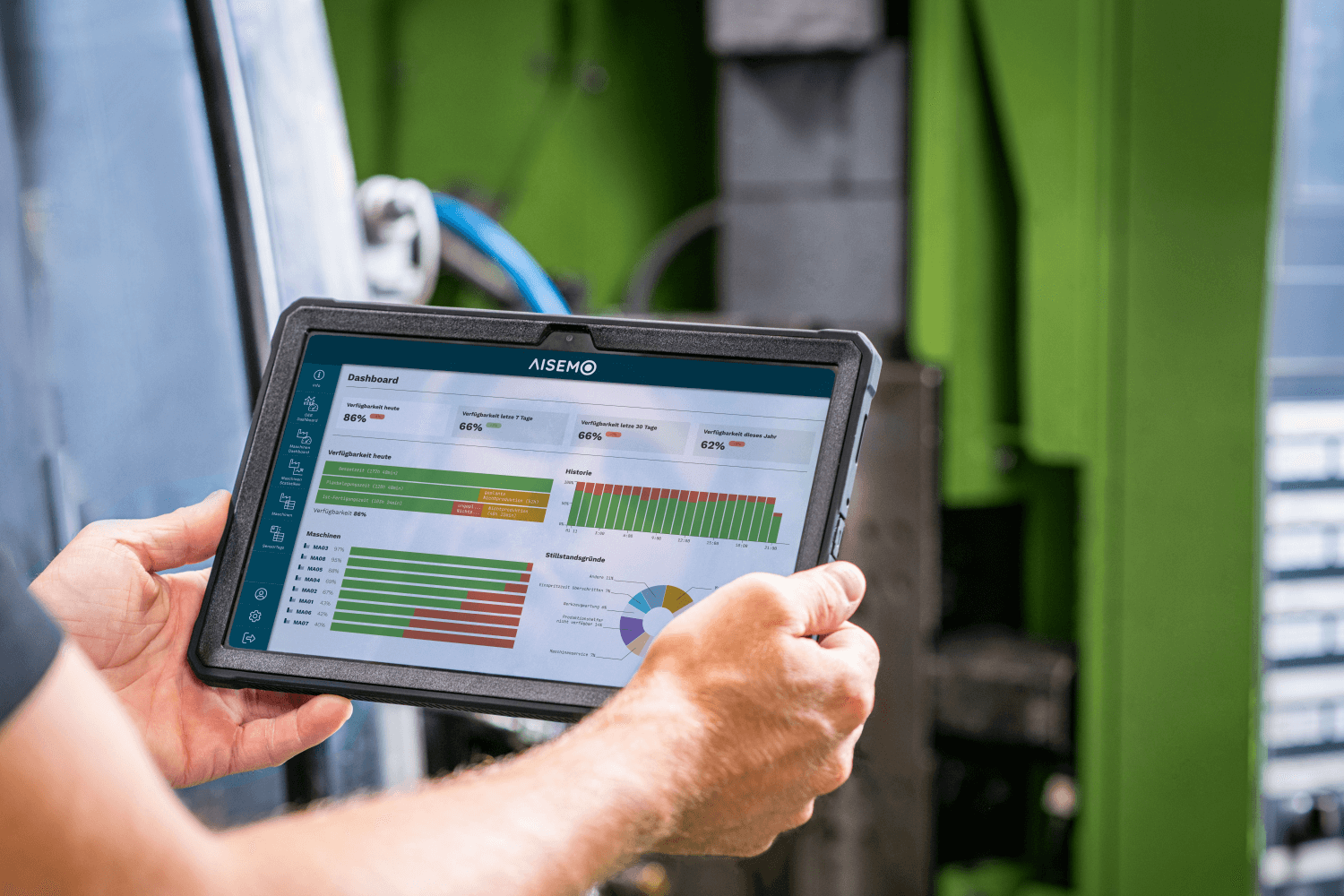

By detecting anomalies in injection molding machines at an early stage, condition monitoring can prevent both unwanted machine downtimes and unnecessary rejects.

In the plastics cluster project “ReGuMa – Reduction of planned and unplanned machine downtimes”, one or two defined error cases were analyzed at each company partner and the possibility of preventing unplanned downtimes was evaluated.

The aim was early fault detection for all types of injection molding machines using non-invasive sensors and intelligent evaluation of the sensor data.

Project partners: AISEMO GmbH, Aspöck Systems GmbH, Ing. Gerhard Fildan GesmbH, Ing. H. Gradwohl GmbH, MKW Kunststofftechnik GmbH, PTM Kunststofftechnologie GmbH.

Requirements

- Early detection of faults on injection molding machines

- Sensor data collection on various types of injection molding machines

- Evaluation of the sensor data

- Project management of the cluster coordination project

Solution

- Hardware

- Support with data analysis

- Coordination of cluster cooperation project

Success story “15% increased productivity through intelligent electronics development”

Erwin Schimbäck

Business Area Manager Sensors & Communication

Further projects

Multifunctional milling machine

Discover how customized functional steels improve the properties of sheet steel and open up new application possibilities.

Analysis of vibrations in pipeline networks

Analysis of vibrations in pipeline networks Piping networks are subject to complex interactions with hydraulic and mechanical components – such…

Adjustable passive vibration damper

Adjustable passive vibration damper Effective vibration reduction for buildings Buildings are exposed to a variety of loads, for example from…