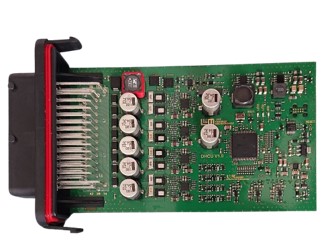

DHCU: Compact Power Electronics for Modern Hydraulic Systems

The Compact Intelligence for Modern Hydraulic Systems

With the Digital Hydraulic Control Unit (DHCU), LCM offers a proprietary electronic unit developed for the precise control of digital hydraulic systems. The DHCU is specifically designed for applications that require short response times, high energy efficiency, and flexible integration – ranging from mobile machinery to industrial automation.

At the core of the solution is a powerful microcontroller, optimized for real-time applications in drive technology. In combination with state-of-the-art power electronics, the DHCU enables precise current control and valve switching times in the millisecond range. The integrated boost-and-hold principle ensures rapid switching with minimal energy consumption.

Typical application areas include mobile hydraulics, industrial hydraulics, and robotics (actuation in force-based robotic systems). Thanks to its compact design (approx. 100 × 125 × 35 mm), the DHCU is ideally suited for direct installation in machines or control blocks. The DHCU is available as a functional prototype and is continuously being developed further. It is a key component in the digital transformation of hydraulic drives and demonstrates how intelligent electronics are opening up new possibilities in fluid technology.

Requirements

- Low efficiency of traditional hydraulic systems

- High maintenance effort and complex valve technology

- Slow switching times with conventional valves

- High energy consumption and significant heat generation

- Manufacturer-independent, flexible system for measurement, control, and regulation tasks

Your Benefits

- Significantly higher energy efficiency through fast, digital switching technology

- Simple and robust design reduces maintenance and costs

- Ultra-fast switching (~1 ms) for precise and dynamic control

- Up to 80% lower energy consumption and reduced heat losses

- Smaller tanks and cooling systems thanks to lower oil temperatures

Advantages of Fast Switching Valves

The fast switching valve FSVi (Fast Switching Valve with integrated Electronics) is a key component for implementing digital hydraulics in industrial applications. At the heart of the valve is a specially developed magnetic actuator that enables extremely high switching speeds.

The development focused on optimizing the interaction between the actuator, the integrated drive electronics, and the mechanical components. The result is a valve that combines high dynamics with low energy consumption. An additional feature is the sensorless temperature monitoring of the magnet, allowing the valve to operate within its optimal temperature range. An integrated algorithm in the control electronics further reduces energy demand.

Fast, efficient, economical

The FSVi valve enables the creation of energy-efficient digital hydraulic circuits, reducing the energy consumption of hydraulic drives by up to 80%. In addition, less heat is generated, meaning smaller or no cooling systems are required.

Lower oil temperatures reduce the system’s oil requirements and allow for smaller tank sizes. This not only decreases overall system costs but also lowers environmental risks.

Bernd Winkler

Business Area Manager Hydraulic Drives

Further Reference Projects

Smart Pump Management Die casting machine/Bühler

Less wear, more efficiency: retrofit solution for die casting systems during operation Smart pump management optimizes hydraulic systems in Bühler…

Synchronized oscillation for higher compaction quality

Increasing the compaction quality of road rollers Digital hydraulic solution optimizes drum synchronization in road construction In cooperation with Hamm…