Simulation and optimization of vibratory conveyor systems

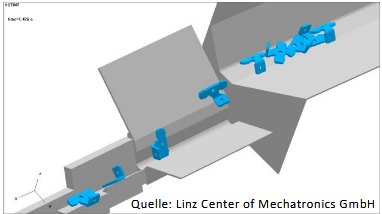

In modern vibratory conveyor systems, the efficiency of the conveyor systems is becoming increasingly important due to increasing customer requirements and competitive pressure. The aim is to ensure that more correctly aligned parts arrive at the end of the chicane in a shorter time, i.e. to increase the power density. The conveying process itself is very complex and also exhibits chaotic behavior, which was investigated in detail as part of a dissertation at LCM. The aim of the project is to develop an (autonomous) chicane designer. Based on simulations, this should suggest a baffle geometry so that the required target values are met in the best possible way.

(Video credit: STIWA Automation GmbH)

StiFSim makes it possible to import geometries directly from the CAD program into the simulation environment. Parameters such as the swing stroke or throwing angle are set there. Modeling the contact between the baffle and the component is a particular challenge.

For this purpose, a contact algorithm was developed in the multi-body dynamics tool HOTINT, which is accessed in the StiFSim environment.

multi-body dynamics tool HOTINT (https://hotint.lcm.at)

Methodology

- Implementation of a contact model for any 3D rigid body in the MKS simulation tool HOTINT

- Parameterization of the MBS model and calibration/validation based on measurements and statistical distributions on a real test bench

Results and benefits

- Model-based development of conveyor systems

- Savings in the design and production of prototypes

- Savings in development costs

- Demonstration of functionality to customers

Find out more in the Success Story

Dipl.-Ing., Dr. Markus Schörgenhumer, BSc

Business Area Manager Mechanics & Control

Further projects

Multifunctional milling machine

Discover how customized functional steels improve the properties of sheet steel and open up new application possibilities.

Simulation and optimization of vibratory conveyor systems

Find out how we use simulation and optimization to increase the efficiency of vibratory conveyor systems and improve industrial processes.

Tailormade Functional Steel – Intelligent sheet steel

Discover how customized functional steels improve the properties of sheet steel and open up new application possibilities.