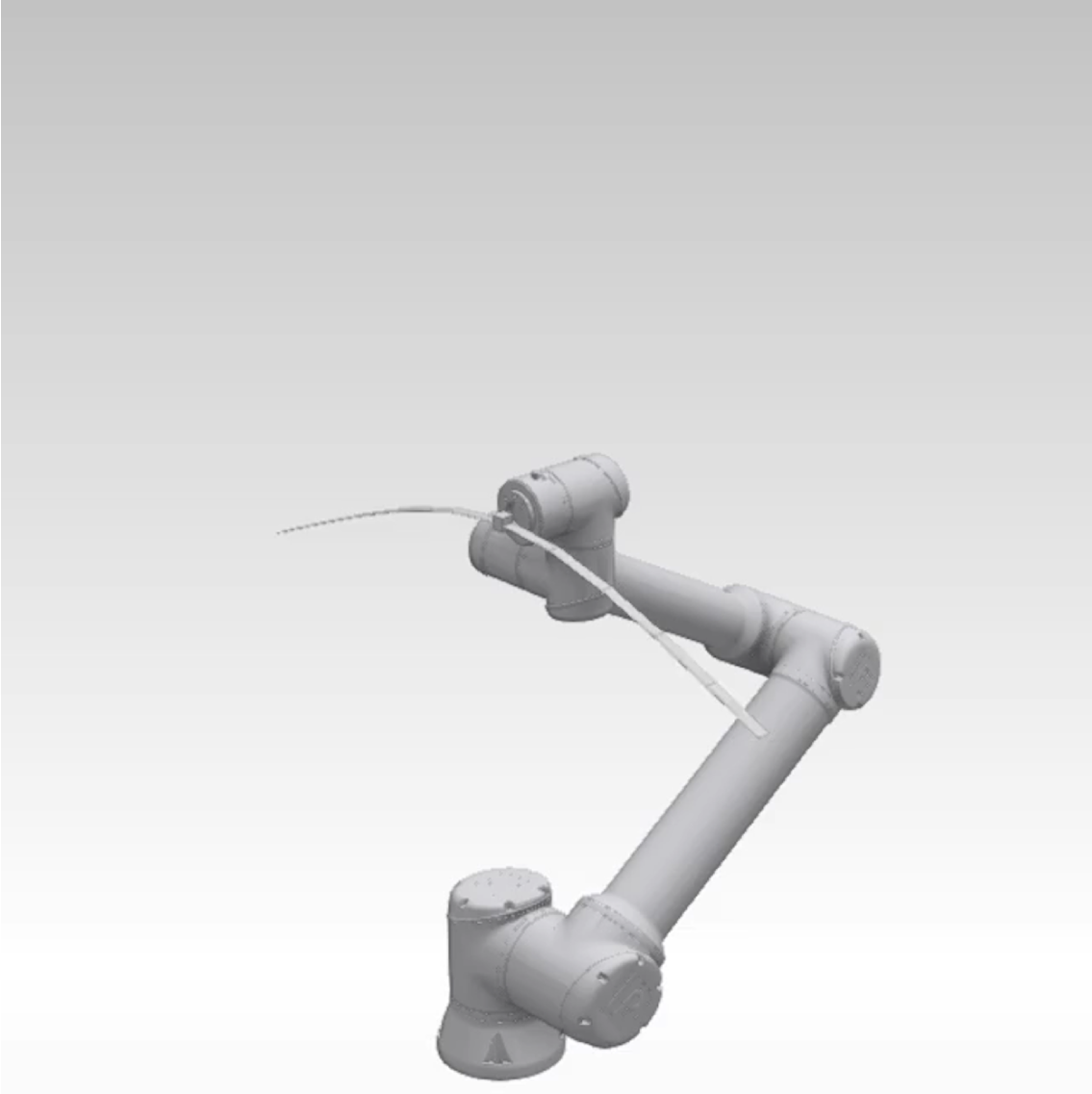

Low-vibration robot movement through model-based trajectory planning

Faster movements of robot arms without oscillations

By taking the elastic properties of components into account in motion planning, vibrations can be reduced and cycle times shortened. The project demonstrates this using a flexible beam with automated code and FMU export for simulation as an example.

Initial situation and requirements

- Fast movements

- Avoidance of vibrations

Solution and benefits

- Modeling, simulation, virtual commissioning

- Trajectory planning with defined speed profile

- Fast movements without oscillations

- Increased throughput

Contact Person

Dipl.-Ing., Dr. Markus Schörgenhumer, BSc

Business Area Manager Mechanics & Control

Further reference projects

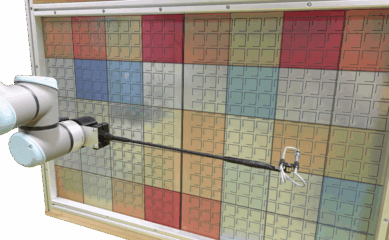

Automated measuring processes using cobots

Automated measuring processes using cobots Seamless combination of robotics and measurement technology A fully automated measurement process combines precise positioning,…

Automated sound intensity measurement

Automated sound intensity measurement Precise evaluation using sound pressure, sound intensity and sound power The system can be used to…

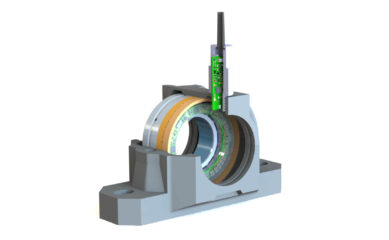

Self-sufficient sensor technology for rolling bearings

Self-sufficient sensor technology for rolling bearings Maintenance-free, wireless data acquisition Together with NKE Bearings, LCM has developed a technology that…