Virtual prototype

Optimum machine design for feeding and sorting systems

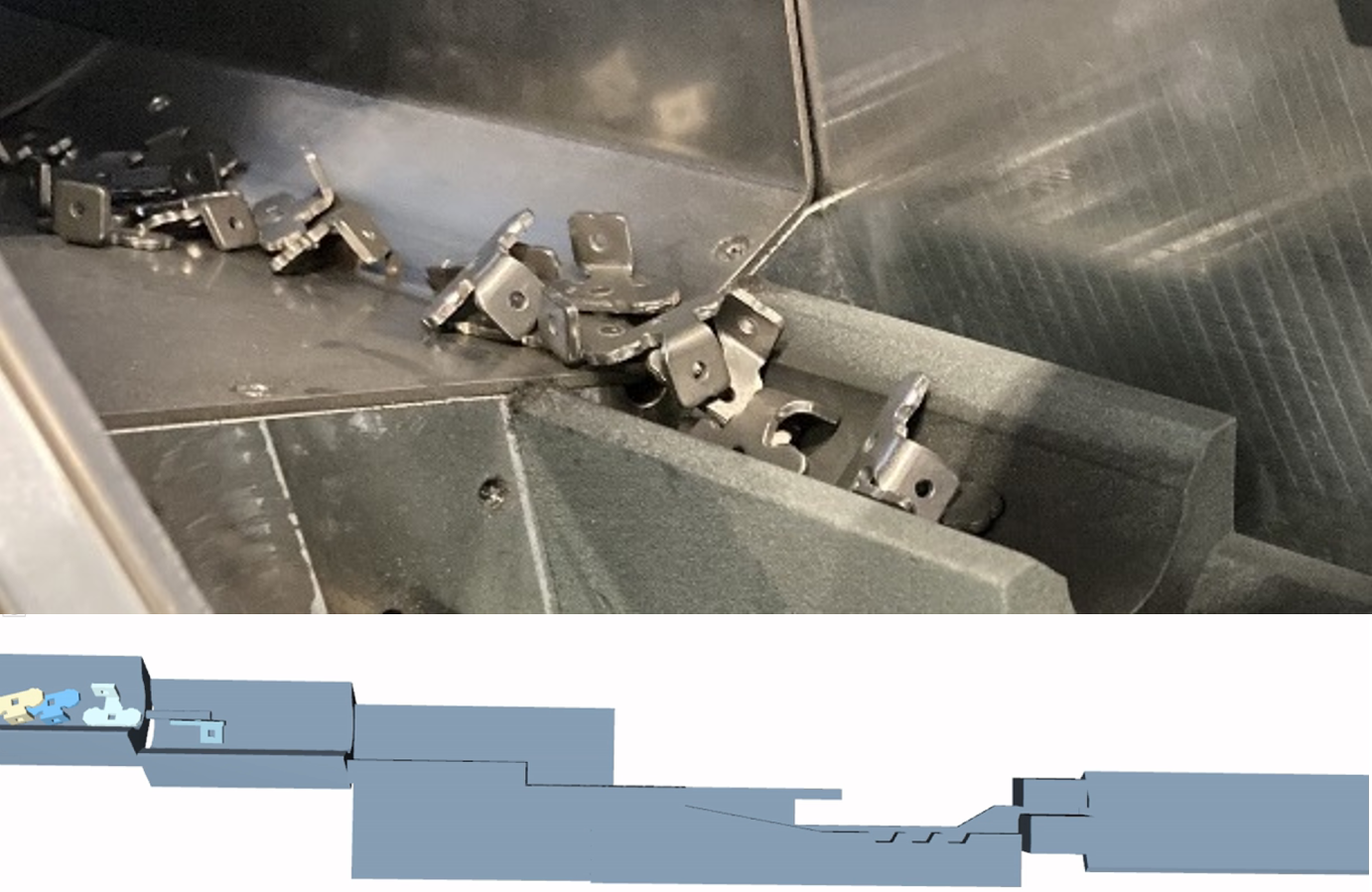

Vibratory conveyor systems are an important component of modern automation systems. Competitive systems require optimum conveying performance by optimizing the baffle geometry. A software tool developed for STIWA Automation GmbH for the design of vibratory conveyor systems has been integrated into the company and is actively used in the manufacturing process.

Requirements

- Separated bulk parts with defined orientation

- Prediction of the appropriate baffle geometry for the desired conveying behavior

Your benefit

- Savings in prototype construction

- Savings in development costs

- Higher process performance

Dipl.-Ing., Dr. Markus Schörgenhumer, BSc

Business Area Manager Mechanics & Control

Further reference projects

Multifunctional milling machine

Discover how customized functional steels improve the properties of sheet steel and open up new application possibilities.

Analysis of vibrations in pipeline networks

Analysis of vibrations in pipeline networks Piping networks are subject to complex interactions with hydraulic and mechanical components – such…

Adjustable passive vibration damper

Adjustable passive vibration damper Effective vibration reduction for buildings Buildings are exposed to a variety of loads, for example from…