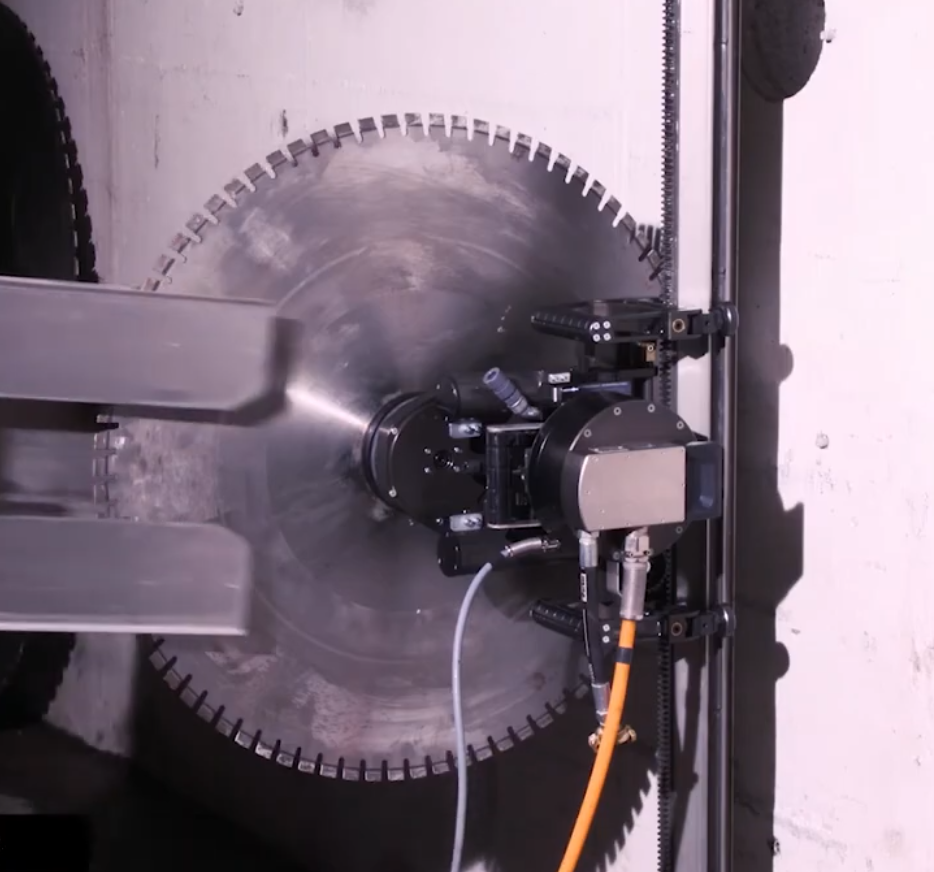

Sensors for rotating machine parts

Tool identification & early fault detection

Rotating machine parts are often exposed to high loads. This can lead to unexpected failures and expensive repairs. The challenge is to detect potential faults at an early stage in order to avoid unplanned downtimes and inefficient maintenance processes.

In certain applications, it is also advantageous to record the operating states and running times of the tools in relation to an identified tool.

In order to be able to continuously record the status of a machine part, it must be identifiable. Unique identification is required to assign the status of a machine part, which is possible using RFID transponders.

Requirements

- Real-time early fault detection by evaluating sensor data directly on the tool

- Wireless communication of sensor data with the machine and a smartphone

- Identification of the tool via an integrated RFID transponder

- Energy-efficient system for long running times with few battery charges or battery changes

Solution

- Continuous recording and wireless transmission of sensor data for early fault detection

- Adapted RFID reader for secure identification even in almost completely metallic environments

- Co-rotating sensors (MEMS, piezoelectric acceleration sensors, temperature measurements) for condition monitoring

- Energy-efficient, embedded electronics for processing and transmitting raw data or filtered monitoring data

- Optimized BLE antennas for reliable communication in metallic environments with water as a cooling medium

Erwin Schimbäck

Business Area Manager Sensors & Communication

Further reference projects

Early fault detection for all injection molding machines

Early fault detection for all injection molding machines Reduction of machine downtimes By detecting anomalies in injection molding machines at…

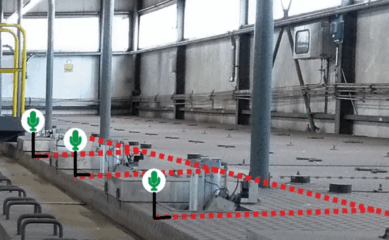

Fault detection in a dedusting system

Condition monitoring of cutting processes Detection of incorrect activation of valves In a dust extraction system, the incorrect switching of…

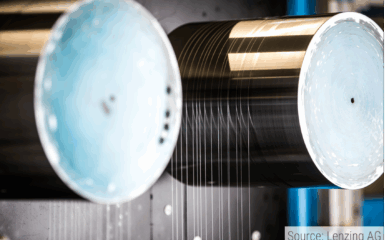

Condition monitoring of cutting processes

Condition monitoring of cutting processes Quality assurance in fiber production Lenzing produces a wide variety of fibers from the raw…