Condition monitoring of cutting processes

Quality assurance in fiber production

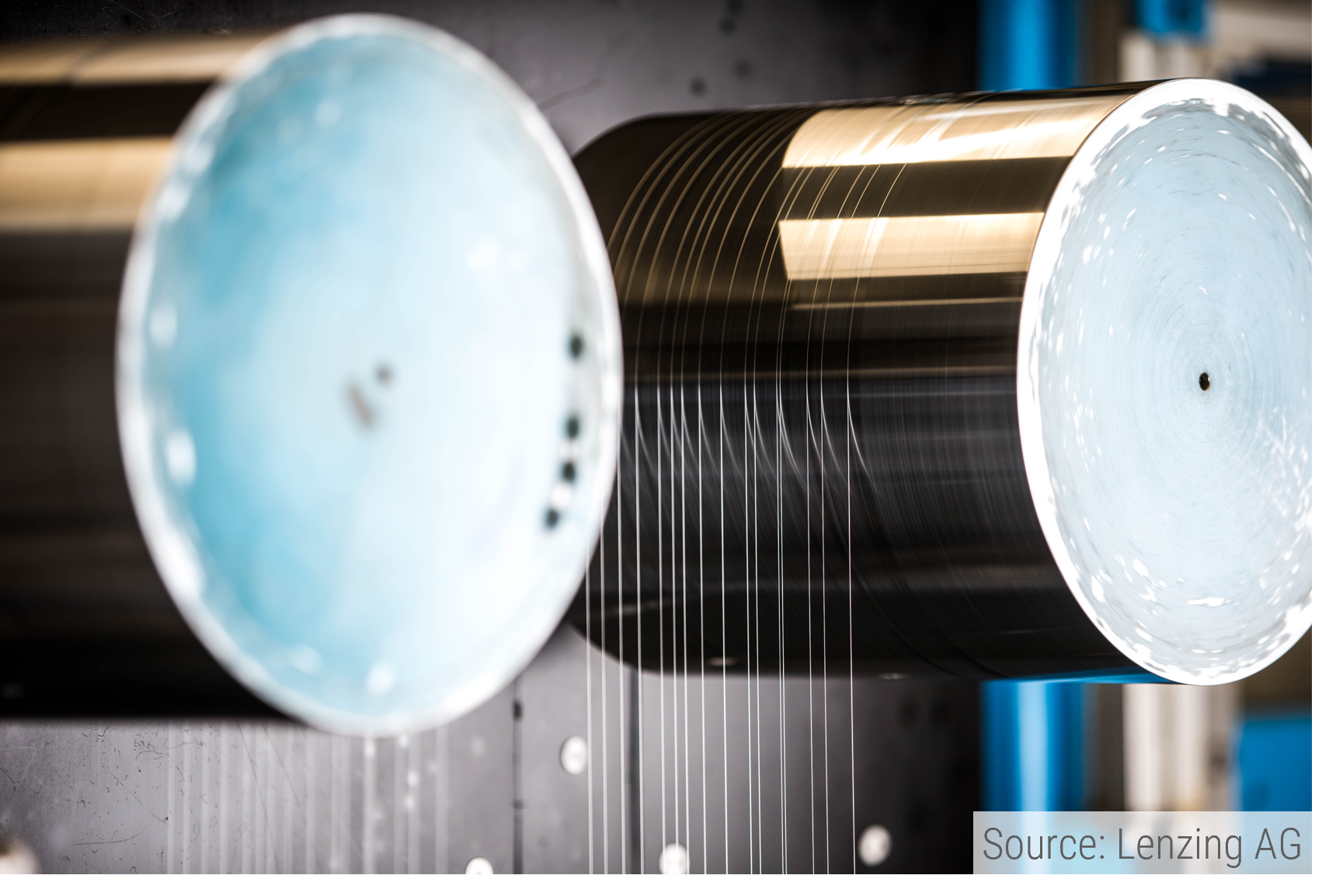

Lenzing produces a wide variety of fibers from the raw material wood. The fibers are later used for both textiles and technical tiles.

During the production process, the fibers must be cut into short pieces.

The wear of the cutting blades has an influence on the quality of the end product, as well as on noise, vibrations and energy requirements.

However, the cutting blades should not be changed too often for economic reasons.

A condition monitoring system was implemented with LCM to automatically monitor wear and determine the ideal time to replace the cutting blades.

Methods & Technology

- Measurement and analysis of vibrations

- Measurement and analysis of noise emissions

- Measurement and analysis of electrical drive currents

Results and benefits for customers

- Improved maintenance planning with information on blade wear

- Predictive condition monitoring of the cutting system

Dipl.-Ing., Dr. Markus Schörgenhumer, BSc

Business Area Manager Mechanics & Control

Further reference projects

BABA emissions

BABA emissions BAtteria-Based energy storage for the mobile provision of EMISSION-free electrical energy The reduction of greenhouse gases (GHG) is…

Automatic sheet metal bending machine

Digital twin in use at Salvagnini Automatic sheet metal bending machine We have developed a digital twin for predictive maintenance….