Condition monitoring of cutting processes

Detection of incorrect activation of valves

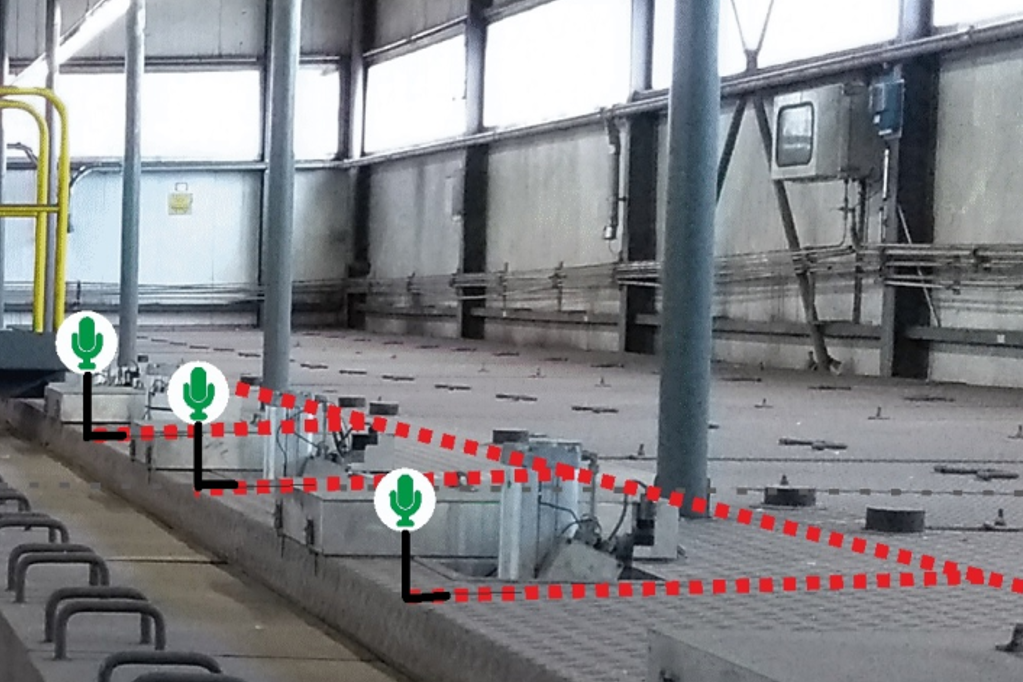

In a dust extraction system, the incorrect switching of valves is to be detected. Due to the strong room acoustics and the reverberation under the valve cover, it is not possible to locate the running time.

Requirements

- Detection of incorrect activation of 280 valves

- Faulty activation of a valve should be detected by localizing the cleaning noise

- Measurement with 16 microphones on the system

Solution

- Improved machine learning approach enables significant reduction in hardware costs

- From over 70 statistical features per cleaning sound and microphone, the five most meaningful are selected for analysis.

Contact Person

Erwin Schimbäck

Business Area Manager Sensors & Communication

Further reference projects

Early fault detection for all injection molding machines

Early fault detection for all injection molding machines Reduction of machine downtimes By detecting anomalies in injection molding machines at…

Fault detection in a dedusting system

Condition monitoring of cutting processes Detection of incorrect activation of valves In a dust extraction system, the incorrect switching of…

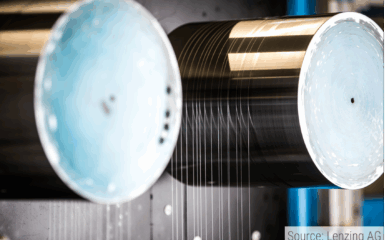

Condition monitoring of cutting processes

Condition monitoring of cutting processes Quality assurance in fiber production Lenzing produces a wide variety of fibers from the raw…