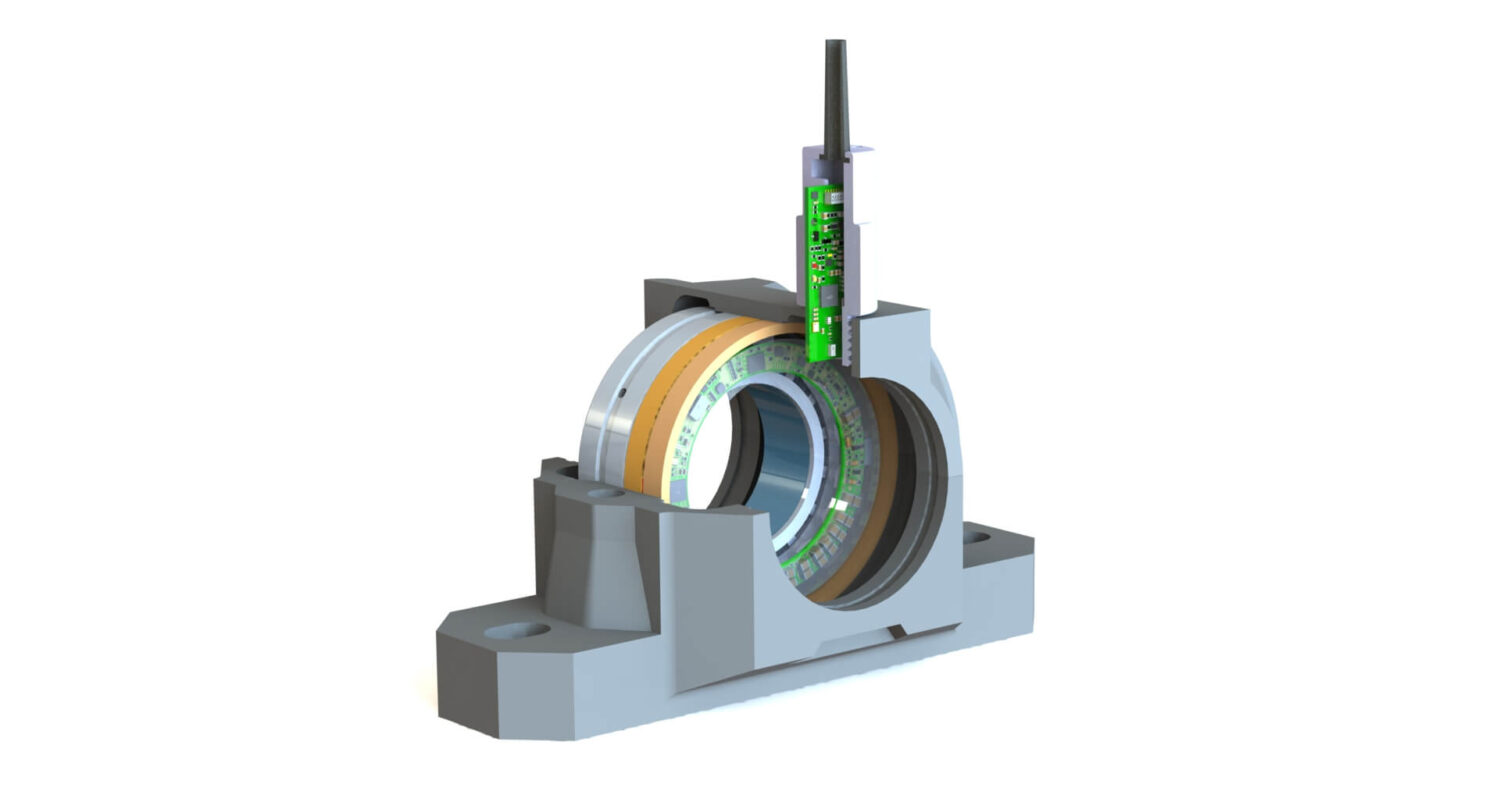

Self-sufficient sensor technology for rolling bearings

Maintenance-free, wireless data acquisition

Together with NKE Bearings, LCM has developed a technology that enables the detection of overheating in rolling bearings. The modular sensor system (MOSS) can be retrofitted and enables real-time data such as bearing temperature and speed to be transmitted wirelessly from the bearing for further analysis. This enables companies to detect faults earlier, carry out predictive maintenance or optimize the warranty monitoring of machines.

Requirements

- Acquisition of measured values directly on the rolling bearing

- Easy to retrofit to existing rolling bearings

- Maintenance-free

- Operating temperature up to 120°C

- No signal or power lines

Available sensors

- Highly robust ring-shaped sensor system

- Pre-processing of sensor data on the electronics

- Transmission of sensor data via Bluetooth

- Autonomous and maintenance-free energy supply through energy harvesting

- Signal relay for bridging metallic encapsulations

- Online monitoring of operating parameters incl. notification by phone call, e-mail, SMS, etc.

Erwin Schimbäck

Business Area Manager Sensors & Communication

Weitere Referenzprojekte

Multifunctional milling machine

Discover how customized functional steels improve the properties of sheet steel and open up new application possibilities.

Adjustable passive vibration damper

Adjustable passive vibration damper Effective vibration reduction for buildings Buildings are exposed to a variety of loads, for example from…

Automatic sheet metal bending machine

Digital twin in use at Salvagnini Automatic sheet metal bending machine We have developed a digital twin for predictive maintenance….