BABA emissions

BAtteria-Based energy storage for the mobile provision of EMISSION-free electrical energy

The reduction of greenhouse gases (GHG) is a priority goal on the political agenda and a necessity for achieving climate targets and limiting the rise in global temperatures. Achieving these goals will require efforts in virtually all sectors of modern life. Many of the solutions to this end take into account the substitution of fossil fuels with electrical (and ideally renewable) energy sources.

The “BABA Emissions” project is aimed at GHG reductions for the construction industry and for firefighting operations, where decarbonization and increased efficiency can be achieved through the use of electro(chemical) storage systems. Currently, construction sites and mobile power supplies are mostly diesel generators or diesel-powered machines.

Goals and innovation content

- GHG reduction through the use of electrochemical storage systems

- Derivation of energy-efficient operating modes on the basis of mathematical models

- Development of application-specific optimization processes

- Modeling of system components for use in optimization

- metrological verification of the operating modes in functional samples

- Use of operational data to determine storage health & maintenance requirements

- Quantification of the effects on GHG emissions, noise and operability

Solution

- Requirements defined for battery systems for construction sites and fire departments

- Methodical procedure developed for modeling and simulating operation

- Functional model built on a laboratory scale (proof-of-concept)

- Concept for the use of operating data for additional functions (e.g. maintenance, condition)

Dipl.-Ing. Dr. Manfred Nader

Chief Scientific Officer (CSO)

Further reference projects

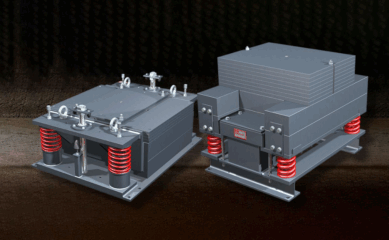

Adjustable passive vibration damper

Adjustable passive vibration damper Effective vibration reduction for buildings Buildings are exposed to a variety of loads, for example from…

BABA emissions

BABA emissions BAtteria-Based energy storage for the mobile provision of EMISSION-free electrical energy The reduction of greenhouse gases (GHG) is…