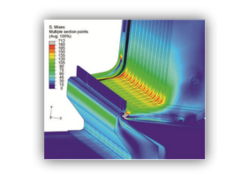

Digital twin in use at Salvagnini

Automatic sheet metal bending machine

We have developed a digital twin for predictive maintenance. We can use it to monitor and calculate the remaining service life of machine components such as bearings, actuators and rotary clamps. This digital twin is based on simulation results and can calculate non-measurable variables such as the development of contact pressure in the bearings during production. By combining virtual sensors and live measurements, we can track the wear of different parts and calculate their remaining useful life.

Requirement

- Improved product quality

- Optimized machine design

- Accelerated commissioning cycles

- Error-free (optimized) operation

- Production with batch size 1

Solution

- Virtual prototype

- Adaptive production process

- Digital product development process

Technology (virtual prototype)

- Lightweight construction, optimized design and efficient drive concepts

- 80% energy saving

- Reduction in the number of hardware prototypes required

Operation (digital twin)

- Automatic detection of material properties (virtual sensor) Fully automatic batch size 1 production

- Automated condition assessment for machine components

Dipl.-Ing., Dr. Markus Schörgenhumer, BSc

Business Area Manager Mechanics & Control

Further reference projects

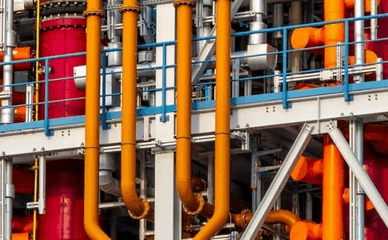

Analysis of vibrations in pipeline networks

Analysis of vibrations in pipeline networks Piping networks are subject to complex interactions with hydraulic and mechanical components – such…

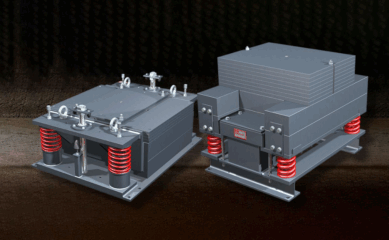

Adjustable passive vibration damper

Adjustable passive vibration damper Effective vibration reduction for buildings Buildings are exposed to a variety of loads, for example from…

BABA emissions

BABA emissions BAtteria-Based energy storage for the mobile provision of EMISSION-free electrical energy The reduction of greenhouse gases (GHG) is…