Shorter cycle times and lightweight construction also in classical plant and machine construction often lead to an increase of unexpected mechanical vibrations. Depending on the application these vibrations can lead to quality problems, noise or even safety-relevant vibrations of buildings.

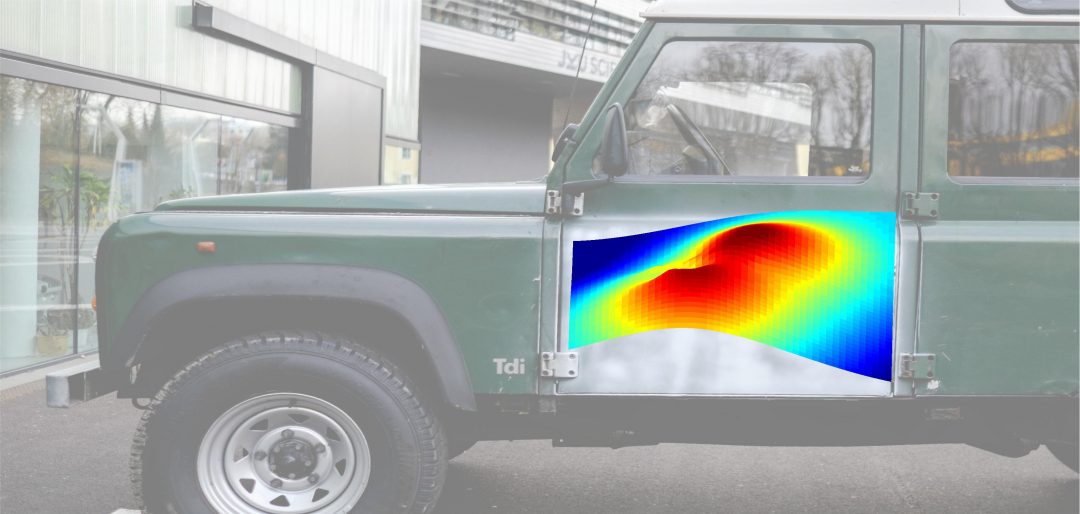

Linz Center of Mechatronics GmbH (LCM) offers measurement based (vibration-) analysis for root cause analysis and identification of possible improvements as well as comparative measurements in a wide frequency range for different application scenarios.

Products, machines and plants are measured and analysed in the relevant mode of operation jointly with customers either directly at the plant or at LCM. Depending on the specific needs of the customer the focus can either be on the identification and removal of the excitation of the vibration, a reduction of the noise radiation or prove evidence of a defined behaviour. Proposals for adaptions are often validated and rated with simulations before the realization of the proposals by the customer.

Available measurement devices:

- digital multi-channel measurement system for recording and analysing data on a laptop

- distance: laser, inductive, radar, ultrasound

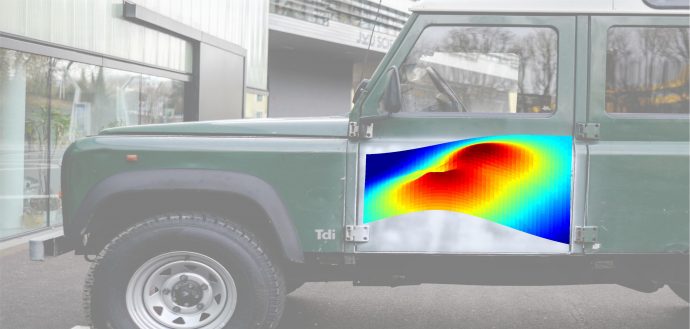

- velocity: laser vibrometer, 2D laser scanning vibrometer

- acceleration: single axis and triaxial accelerometers

- rotational speed

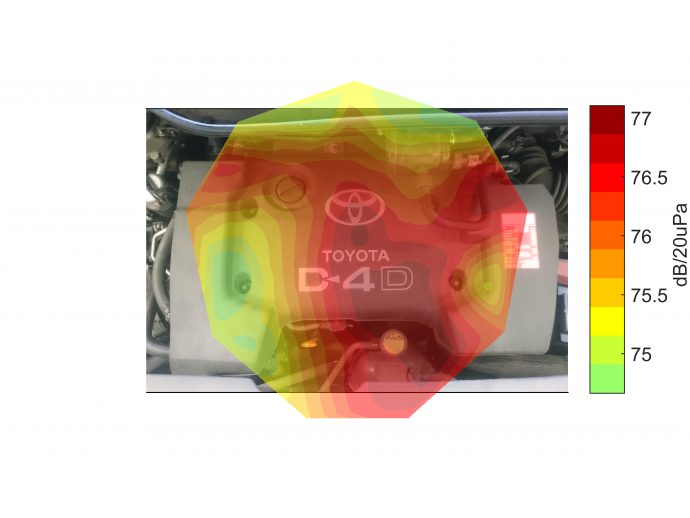

- sound: sound intensity probe, microphones, microphone array

- force, torque and hydraulic pressure

- mechanical deformations (strain gauges)

- current and voltage

- excitation: impulse hammer, shaker, loudspeaker, piezoelectric actuator

Examples of analysis:

- modal analysis (eigenfrequencies, mode shapes of vibration)

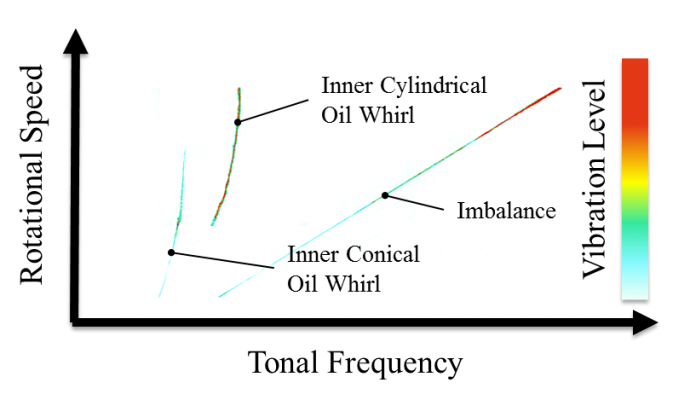

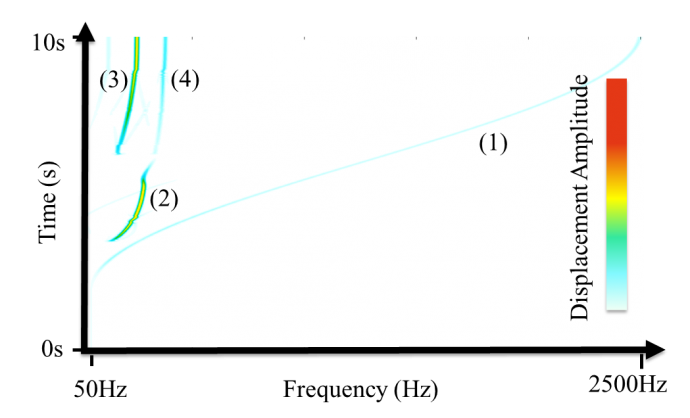

- operational modal analysis (e.g. run-up, stationary operation, waterfall diagrams, order analysis)

- sound source locating

- failure analysis (e.g. bearing defects, inaccurate assembly)

Examples of possible proposals for adaption:

- change of the mass distribution or design

- increase of damping or stiffness in a certain area

- change of the control

- replacement of a certain component (e.g. of the drive)

- reduction of the installation tolerances of certain parts

- active and passive vibration damping