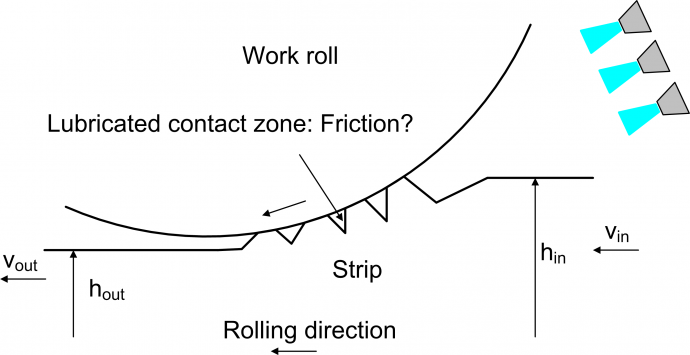

In cold rolling, friction between the workpiece and the work roll influences force and power requirements of the mill as well as the surface quality of the rolled strip. In many cold rolling models, empiric process knowledge is required to properly estimate friction. In this project, a simulation model was developed, which enables the calculation of local pressures and shear stresses based on the properties of the applied lubricant and on the contact conditions. Parametric studies with this model support the design and optimisation of rolling mills, pass schedules and the development of new, specific lubricants.

In cold rolling of flat metal products, lubrication is used in order to reduce friction between the work roll and the work piece, which is deformed plastically. Considering the roughness of the work roll and of the strip, the film thickness usually generated leads to an operation of the process in the so-called mixed lubrication regime, i.e. the interface pressure is partly carried by asperity contact and by the lubricant.

The computer-simulation of this process (e.g. in order to predict force and power of a mill stand) requires incorporating mechanisms of hydrodynamic flow as well as elastic and/or plastic deformation of the contact partners (elasto-plasto-hydrodynamic contact). Due to convergence issues and enormous calculation times of possibly weeks and months, it is hardly possible to accomplish this task in full detail by the usage of general-purpose commercial simulation tools (FEM, CFD, …), .

In the presented project, a very specific and tailor-made simulation model has been developed, which enables the prediction of shear stresses and pressures in the roll bite based on an analysis of the contact situation (i.e. the fraction of asperity contact compared to lubricated contact) and on the properties and composition of the applied lubricant. This model relies on reduced, yet accurate sub-models of the involved mechanisms, and allows for obtaining robust and converging results within minutes.