In accordance with the principle ‘Keep it smart and simple’, digital valves are initiating a modernization thrust in the field of hydraulics. Thanks to their simple design, they are low-cost, low-maintenance and they will also convince you with their unrivalled precision, energy efficiency and reliability. This makes digital valves the pacesetter in development work on hydraulic systems. They are providing for enormous increases in efficiency in the field of heavy construction and forestry machinery, automotive drives and throughout the machine construction industry and paper industry. With switching times of just a few milliseconds, digital valves are setting new standards for the positioning precision of drives, significantly increasing reliability and dramatically reducing energy consumption.

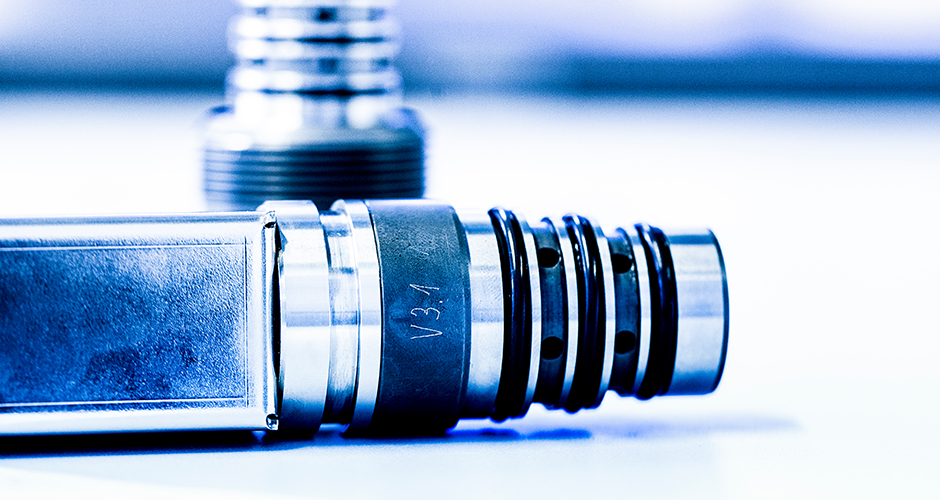

The outstanding force and power density of hydraulic systems is often overshadowed by their low energy efficiency. This is where digital hydraulic circuit concepts come into play. The core element is the fast switching valve. LCM has developed and built the first fast switching valve for digital hydraulics, the FSVi (Fast Switching Valve with integrated electronics), which with a switching time of roughly 1 ms is at least five times faster than any other valve on the market.

Optimized magnets and energy efficient triggering, which is embedded in the integrated electronics of the valve, provide for an unrivalled continuous switching frequency of 100 Hz. In addition to these technical achievements, the FSVi lowers the production and maintenance costs of hydraulic drives through its simple construction.

BENEFITS OF FAST SWITCHING VALVES

From a technological point of view, the fast switching valve FSVi was the previously missing link required to make digital hydraulics usable for industrial applications. The core component of the valve is a power-optimized magnetic actuator, which generates unrivalled dynamics.

The technological creativity results primarily from an holistic approach to development. The interaction of the magnetic actuator with the electrical triggering electronics and the mechanical components has been optimized. Thanks only to this was it possible to develop a highly dynamic valve that at the same time enables energy-efficient operation. An additional innovation is SENSORLESS temperature measurement of the magnet, which ensures operation within a temperature- and therefore energy-optimized range. The implementation of an intelligent algorithm in the control electronics once again reduces the energy consumption of the valve.

FAST, EFFICIENT, ECONOMICAL

The FSVi digital valve enables the implementation of energy-efficient digital hydraulic converter circuits. This considerably increases the efficiency of such hydraulic drives and the energy consumption is reduced by up to 80%. At the same time the waste heat of digital hydraulic drives is drastically reduced in comparison to conventional drives. This allows a significant reduction in the size of the cooling systems—these often becoming entirely superfluous. The secondary consumption of the systems is reduced automatically by this factor. Lower oil temperatures reduce the oil volumes in the system and the size of the tanks. This reduces the system costs and, above all, the environmental risk.

Please contact us for further information!

Linz Center of Mechatronics GmbH | Science Park | Altenberger Straße 69 | 4040 Linz | Austria | T +43 732 2468-6002 | F +43 732 2468-6005 | office@lcm.at | www.lcm.at