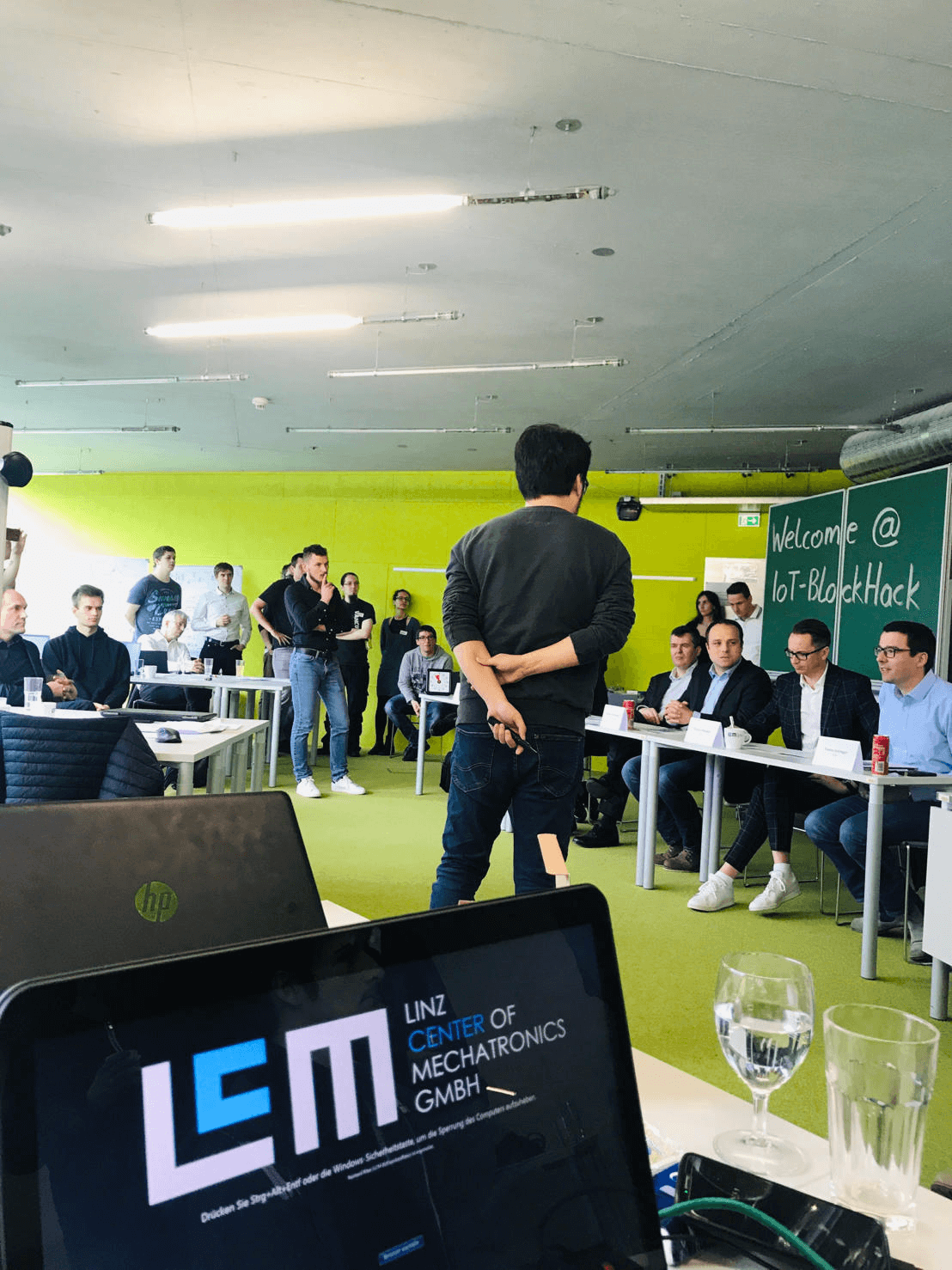

“IoT BlockHack – Physical World Meets Blockchain” – companies implementing this title in a hackathon on 27.02-01.03.2019 at the Linz Center of Mechatronics GmbH (LCM) together with students from the HTL Perg and students of the Johannes Kepler University (JKU ) industry-specific blockchain use cases. The teams were supported by IoT and Blockchain experts from the two organizers Atos & LCM.

The participating companies were AMAG Austria Metal, KEBA, Greiner Bio-One, the STIWA Group and Quality Austria.

In addition to “hacking”, fundamentalthe decisions had to be answered: What are the benefits of the Blockchain-based solution? What steps are required for cross-company implementation? The arguments developed are indispensable for the strategic decisions in the participating companies.

Already in the run-up to the event, the participants outlined their blockchain applications, which were then further developed during the hackathon in mixed teams and with intensive collegial case-related advice:

The use case of AMAG Austria Metall AG serves to ensure the origin and quality of the produced, delivered and circulating aluminum products. Blockchain technology makes it possible to protect product-related data from deliberate and unconscious changes. Product specifications are protected from being changed by being stored and managed in a trusted external database. This benefits both customers and producers. In particular, in sensitive applications, such as in the aviation industry, this approach can contribute to operational safety and to clarify any liability issues.

The company KEBA realized an auditable documentation of machine performance data using the example of energy consumption. In the process, increased energy efficiency in production machines is to be measured and countersigned by the customer. The optimization of process parameters thus leads to a comprehensible added value.

Quality Austria examined the use of Blockchain technology for a transparent audit process with several stakeholders. The particular challenge is to document the communication of the triangular relationship between customer, auditor and certification authority in chronological order without interruption and in an accessible manner.

The two companies Greiner Bio-One and STIWA Group boarded with a cooperative use case: Tracking blood samples in an automated laboratory environment always poses new challenges. Greiner Bio-One and STIWA Group have developed a demonstrator for tracking blood tubes with a graphic interface. The successful company duo emerged from their mature business idea and an impressive implementation as an IoT BlockHack winner.

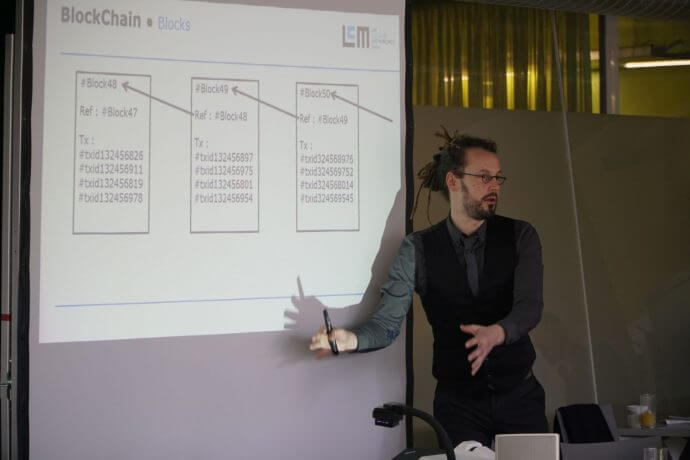

The development framework was the MultiChain. This could be addressed via different interfaces and also allowed the integration of hardware sensors such as temperature sensors or QR code scanners.

Through mutual pitching, the teams have not only helped themselves, but also each other. The relaxed working atmosphere and an actively practiced feedback culture gave the team members an enormous increase in performance and, after just two and a half days, achieved a considerable overall result. In the mixed teams, company representatives, experts as well as pupils and students were able to contribute their strengths. All teams were able to demonstrate on the third day of the jury executable Blockchain prototypes and represent the added value through creative pitches.

The IoT BlockHack enabled the first successful hands-on experience and ensured that the participating companies lost a sometimes too great respect for this technology of the future. This result now provides the ideal stage for the strategic decision-making of the companies.

A re-run of the event for the second half of 2019 is already planned at Atos & LCM.